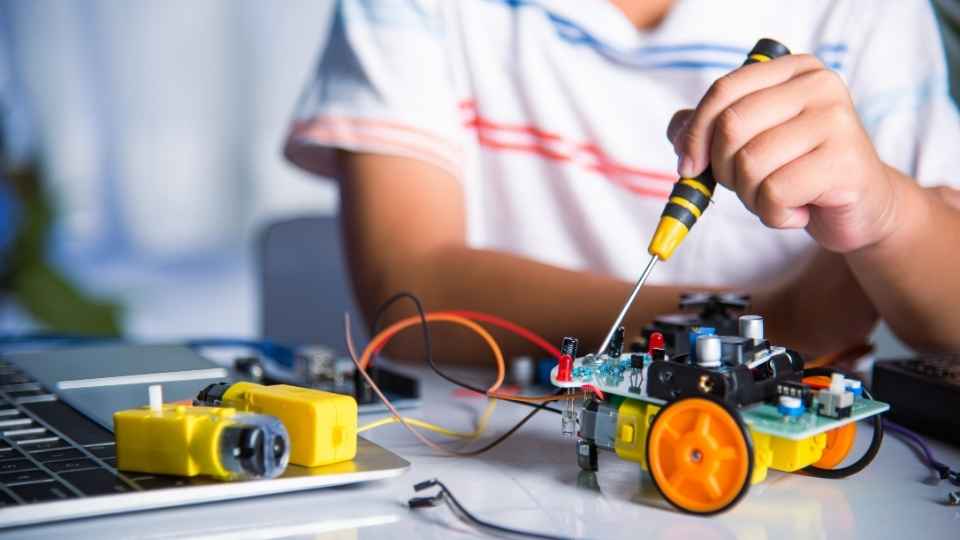

In today's fast-paced world, the use of electronics has become an indispensable part of our daily lives. From smartphones to laptops, these devices have revolutionized how we communicate and access information.

However, with this increasing reliance on technology comes the need for proper handling and maintenance to ensure their optimal performance and longevity. One such aspect that cannot be overlooked is Electrostatic Discharge (ESD) protection.

In this article, we will explore the importance of ESD protection and delve into whether anti-static wrist straps and ESD mats are indeed essential for safe electronics handling.

Key Takeaways

- ESD protection is crucial to safeguard sensitive components from potential damage caused by electrostatic discharge.

- Anti-static wrist straps provide a safe path for static electricity to flow away from the body and are essential for anyone working with sensitive electronics.

- ESD mats dissipate static electricity and minimize the risk of damage to delicate components, providing a conductive surface and controlled path for static electricity to flow away from devices.

- Grounding cords prevent the accumulation of electric charges, ensuring the safety of workers and protecting electronic devices and machinery from ESD-related damage.

The Importance of ESD Protection in Electronics Handling

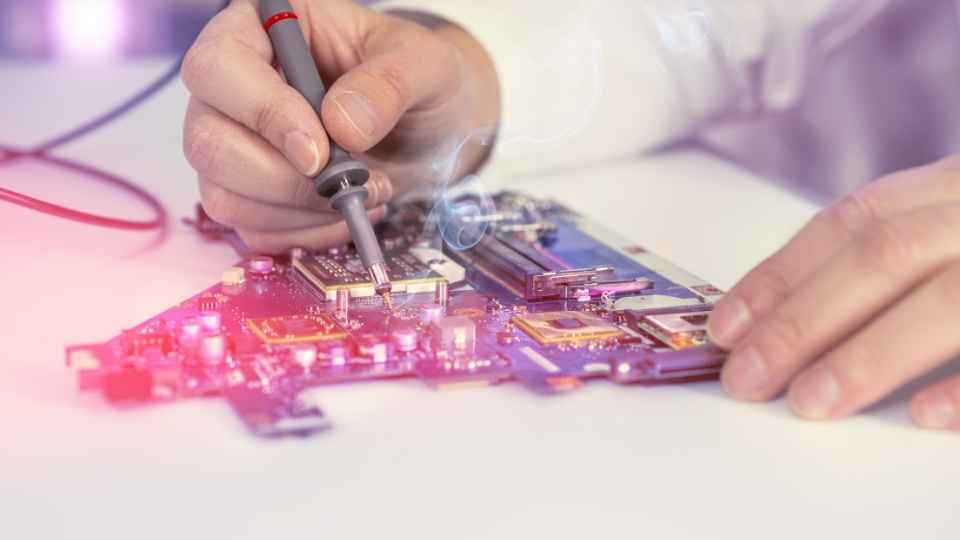

ESD protection is crucial in electronics handling as it safeguards sensitive components from potential damage caused by electrostatic discharge. Electrostatic discharge occurs when there is a sudden flow of electric current between two objects with different electrical potentials, resulting in the release of energy. This discharge can easily occur during the handling or assembly of electronic components, especially in environments where static electricity is generated.

The consequences of ESD can be disastrous for electronic devices. It can lead to immediate failure or latent damage, reducing their reliability and lifespan. The damage caused by ESD may not be immediately apparent but can manifest over time, causing intermittent malfunctions and premature failures.

To prevent such issues, proper ESD protection measures must be implemented. These include using anti-static wrist straps and ESD mats to safely dissipate any static charge that may accumulate on the operator or work surface. Understanding how these tools work in preventing ESD is essential for maintaining a safe working environment while handling delicate electronics.

Understanding Anti-Static Wrist Straps for ESD Prevention

In order to prevent damaging electronic components due to electrical discharge, it is important to have a thorough understanding of the function and use of anti-static wrist straps. These wrist straps are an essential tool for anyone working with sensitive electronics, as they provide a safe path for static electricity to flow away from the body.

Here are three key points to consider when using anti-static wrist straps:

Design: Anti-static wrist straps typically consist of a conductive strap made from materials such as carbon fiber or metal, which is connected to a grounding point. The strap is usually adjustable and comfortable to wear for extended periods.

Proper Usage: To ensure effective protection, it's crucial to properly connect the strap to a grounded surface, such as an ESD mat or ground plug socket. The strap should be worn snugly around the wrist, with good contact between the skin and strap.

Maintenance: It's essential to regularly test the functionality of anti-static wrist straps using an ESD tester or multimeter. Additionally, inspecting the strap for any signs of wear or damage is necessary and replacing it if needed.

ESD Mats: A Crucial Component for Safe Electronics Handling

ESD mats provide a conductive surface for electronics handling, effectively dissipating static electricity and minimizing the risk of damage to delicate components. These mats are made from materials with high electrical conductivity and low resistance, ensuring that any static charges generated by human contact or other sources are quickly discharged into the ground.

The main purpose of an ESD mat is to create a controlled path for static electricity to flow away from sensitive electronic devices, preventing electrostatic discharge (ESD) events that can cause irreversible damage.

In addition to their conductive properties, ESD mats also offer anti-slip surfaces and cushioning for added protection against accidental drops or impacts. Proper grounding of the mat is crucial for its effectiveness, as it allows for the safe dissipation of static charges without posing any risk to personnel or equipment.

Therefore, when working with electronics in environments where static electricity is a concern, using ESD mats is essential to ensure the safety and integrity of sensitive components.

Grounding Cords: Enhancing ESD Protection in the Workplace

Grounding cords play a crucial role in enhancing the safety measures against static electricity in the workplace. They provide a direct path for static discharge, preventing the accumulation of electric charges on objects and equipment.

Here are three key benefits of grounding cords:

Electrostatic discharge (ESD) prevention: Grounding cords help to dissipate static charges from electronic devices, reducing the risk of ESD damage. By providing a low-resistance path to ground, they ensure that electrical charges are safely discharged away from sensitive components.

Personnel protection: Grounding cords are essential for ensuring the safety of workers handling electronic equipment. By connecting workers to ground, they prevent any potential buildup of static charge on their bodies, minimizing the risk of painful shocks or sparks.

Equipment protection: In addition to protecting personnel, grounding cords safeguard electronic devices and machinery from ESD-related damage. By channeling excess current directly to ground, they prevent high voltages from reaching sensitive components and causing irreversible harm.

With an understanding of the importance of grounding cords in ESD protection, it is necessary to explore additional measures like protective anti-static bags and ionizing fans in further detail.

The Role of Protective Anti-Static Bags and Ionizing Fans in ESD Prevention

To enhance workplace safety against static electricity, it is important to consider the role of protective anti-static bags and ionizing fans in preventing ESD-related issues.

Protective anti-static bags are designed to shield electronic components from electrostatic discharge (ESD) during storage and transportation. These bags are made with a special type of material that eliminates or reduces static charges, ensuring that the sensitive electronic devices within remain safe.

Additionally, ionizing fans play a vital role in ESD prevention by neutralizing static charges in the surrounding air. These fans emit ions that attract and neutralize charged particles, thereby minimizing the risk of ESD occurring when handling electronic components.

Frequently Asked Questions

How Do I Properly Use an Anti-Static Wrist Strap for ESD Prevention?

Proper usage of an anti-static wrist strap for ESD prevention involves connecting one end to a grounded surface and the other end to your wrist, ensuring continuous contact during electronics handling.

Are ESD Mats Necessary for All Types of Electronics Handling?

ESD mats are necessary for safe electronics handling as they provide a conductive surface that dissipates static electricity. They protect sensitive components from damage caused by electrostatic discharge, ensuring the integrity and reliability of electronic devices.

Can Grounding Cords Be Used as a Standalone ESD Protection Measure?

Grounding cords alone cannot provide sufficient ESD protection for safe electronics handling. While they can help dissipate static electricity, additional measures such as anti-static wrist straps and ESD mats are essential for comprehensive protection.

What Are the Benefits of Using Protective Anti-Static Bags for Electronics Storage?

Protective anti-static bags offer several benefits for electronics storage. They prevent electrostatic discharge (ESD) damage, shield against dust and moisture, provide insulation from physical damage, and facilitate proper labeling and organization of electronic components.

How Do Ionizing Fans Contribute to ESD Prevention in the Workplace?

Ionizing fans contribute to ESD prevention in the workplace by neutralizing static charges on surfaces and minimizing the risk of electrostatic discharge. They help create a controlled environment for safe electronics handling.

Basic Electronics ConceptsEssential ToolsCircuit Design BasicsMicrocontrollersDIY Electronics ProjectsRoboticsPrivacy PolicyTerms And Conditions

Basic Electronics ConceptsEssential ToolsCircuit Design BasicsMicrocontrollersDIY Electronics ProjectsRoboticsPrivacy PolicyTerms And Conditions