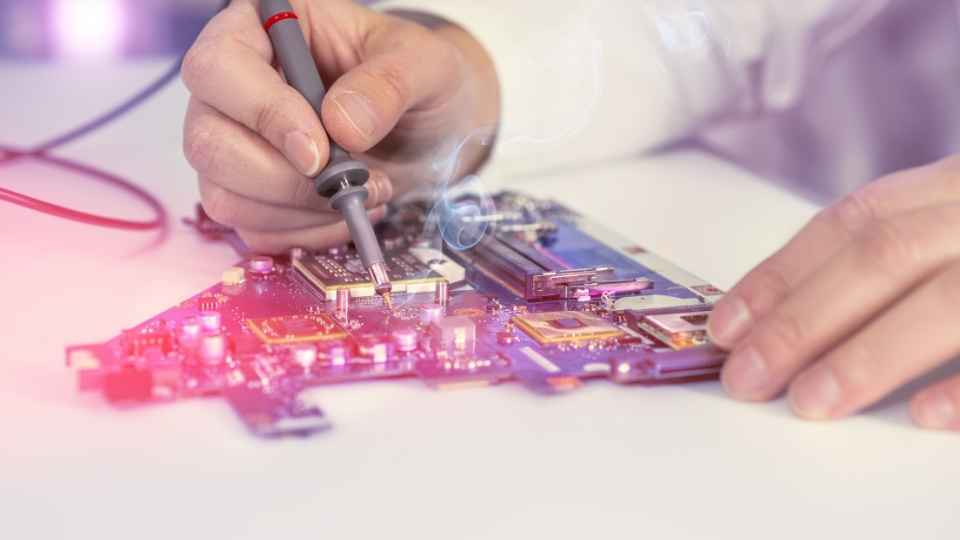

In the world of soldering, choosing the right type of solder can make all the difference in achieving optimal results. When it comes to deciding between rosin core and leaded solder, understanding their differences and advantages becomes crucial.

This article aims to demystify these two solder types and shed light on why choosing rosin core solder may be a wiser choice over leaded solder. By examining factors such as efficiency, safety, and environmental impact, readers will gain valuable insights into making informed decisions when it comes to selecting the most suitable solder for their projects.

Key Takeaways

- Rosin core solder is preferred over leaded solder due to its enhanced safety and reduced health risks associated with lead.

- Choosing rosin core solder is environmentally friendly as it helps in the reduction of harmful substances released into the environment.

- Rosin core solder offers improved soldering performance with better wetting and flow characteristics, resulting in stronger and more reliable solder joints.

- The versatility of rosin core solder makes it suitable for various applications, providing flexibility in different soldering tasks.

The Difference Between Rosin Core and Leaded Solder

When comparing solder types, it is important to understand the difference between rosin core and leaded solder.

Rosin core solder, also known as flux-cored solder, contains a flux core at its center. The flux is a chemical compound that aids in the soldering process by removing oxidation from the surfaces being joined. This type of solder is commonly used for electrical and electronic applications due to its ability to effectively remove contaminants and ensure strong connections.

Leaded solder, on the other hand, contains lead as one of its main components. While lead has desirable properties for soldering purposes, such as low melting point and good wetting characteristics, there are concerns about its environmental impact and potential health hazards. As a result, many countries have restricted or banned the use of leaded solder due to these concerns.

For those who desire freedom from potentially harmful substances and want to follow environmentally-friendly practices, rosin core solder offers a suitable alternative to leaded solder. By choosing rosin core solder, individuals can ensure quality connections while minimizing their impact on the environment and promoting safer working conditions.

Advantages and Disadvantages of Rosin Core Solder

One important consideration when using rosin core solder is understanding its advantages and disadvantages in various applications.

Rosin core solder offers several benefits that make it a popular choice among professionals and hobbyists alike. These advantages include:

- Easy application: The rosin flux within the solder helps to remove oxidation from the surface being soldered, ensuring a strong bond.

- Clean residue: Unlike leaded solder, which can leave behind harmful residues, rosin core solder produces minimal residue that is non-toxic and easy to clean.

- Improved conductivity: The rosin flux promotes better electrical conductivity by reducing the formation of oxides on the joint.

- Versatility: Rosin core solder can be used for a wide range of applications, including electronics repair, plumbing, jewelry making, and more.

However, there are also some potential drawbacks to consider when using rosin core solder. These include:

- Limited strength: Rosin core solder may not provide as strong of a bond as other types of solder such as lead-free or silver-based solders.

- Temperature sensitivity: High temperatures during the soldering process can cause the rosin flux to evaporate quickly, affecting its effectiveness.

- Cleaning requirements: While rosin residue is easier to clean compared to leaded residues, it still requires proper cleaning techniques and materials to ensure optimal performance.

Understanding these advantages and disadvantages will help you make an informed decision about whether rosin core solder is suitable for your specific application needs.

Understanding the Efficiency of Rosin Core Solder

Understanding the efficiency of rosin flux is crucial for determining its effectiveness in various soldering applications.

Rosin flux, also known as rosin core solder, is widely used in electronic and electrical industries due to its excellent solderability and reliability.

The efficiency of rosin flux refers to its ability to remove oxides from metal surfaces, promote wetting between the solder and the substrate, and prevent oxidation during the soldering process.

This efficiency is influenced by factors such as the type and concentration of rosin used, temperature, duration of heating, and surface cleanliness.

A highly efficient rosin flux will provide strong and durable solder joints with minimal defects like voids or cold joints.

It ensures improved electrical conductivity while maintaining long-term stability even under harsh operating conditions.

Therefore, understanding the efficiency of rosin flux enables professionals to choose the most suitable product for their specific soldering requirements.

Exploring the Benefits of Choosing Rosin Core Over Leaded Solder

Exploring the advantages of selecting rosin flux with a core made from non-toxic materials can lead to safer and more environmentally friendly soldering practices.

Rosin core solder offers several benefits over leaded solder, making it a preferred choice for those who desire freedom in their soldering processes.

Enhanced Safety: Rosin core solder eliminates the health risks associated with leaded solder, ensuring a safer working environment.

Environmental Friendliness: With its non-toxic composition, rosin core solder reduces the release of harmful substances into the environment during and after use.

Improved Soldering Performance: The flux within the rosin core promotes better wetting and flow characteristics, resulting in reliable and efficient connections.

Versatility: Rosin flux can be used on various materials, including copper, brass, and nickel alloys, providing flexibility in different applications.

Factors to Consider When Choosing Between Rosin Core and Leaded Solder

When deciding between rosin core and leaded solder, it is essential to consider factors such as safety, environmental impact, soldering performance, and versatility.

Safety is a paramount concern, especially for those working in confined spaces or with limited ventilation. Leaded solder poses health risks due to its lead content, while rosin core solder is lead-free and therefore safer to use.

The environmental impact should also be taken into account; leaded solder contributes to soil and water pollution when improperly disposed of.

In terms of performance, rosin core solder offers excellent wetting capabilities and flux activity, resulting in reliable joints.

Lastly, versatility plays a crucial role; rosin core solder can be used in various applications like electronics assembly or plumbing repairs.

Considering these factors will help individuals make an informed decision that aligns with their safety concerns, environmental values, and desired soldering outcomes.

Frequently Asked Questions

How Is the Melting Point of Rosin Core Solder Different From Leaded Solder?

The melting point of rosin core solder is typically lower than that of leaded solder. This is due to the composition of the flux, which lowers the melting temperature to allow for easier application and joining of electronic components.

Are There Any Safety Concerns When Using Rosin Core Solder?

When using rosin core solder, it is important to be aware of potential safety concerns. These can include exposure to harmful fumes when the solder is heated, as well as the risk of burns from molten solder. Proper ventilation and protective equipment should be used to mitigate these risks.

Can Rosin Core Solder Be Used for All Types of Soldering Applications?

Rosin core solder can be used for various soldering applications due to its flux core, which helps in cleaning and removing oxides from the surfaces being soldered. It is suitable for electronics, plumbing, and other general purpose soldering tasks.

Is Rosin Core Solder More Expensive Than Leaded Solder?

Rosin core solder is generally more expensive than leaded solder due to the additional cost of incorporating flux. However, the benefits it offers in terms of ease of use and reliability often justify the higher price for many professionals in various soldering applications.

What Are Some Common Misconceptions About Rosin Core Solder?

What are some common misconceptions about rosin core solder? It is often mistakenly believed that rosin core solder is less reliable and weaker than leaded solder, but in reality, it offers numerous benefits such as better heat transfer and reduced risk of corrosion.

Basic Electronics ConceptsEssential ToolsCircuit Design BasicsMicrocontrollersDIY Electronics ProjectsRoboticsPrivacy PolicyTerms And Conditions

Basic Electronics ConceptsEssential ToolsCircuit Design BasicsMicrocontrollersDIY Electronics ProjectsRoboticsPrivacy PolicyTerms And Conditions