In the world of electronics, desoldering tools are essential for removing soldered components without causing damage. Two popular options are the hot air gun and the solder sucker.

Like two sides of a coin, these tools possess unique features that make them effective in their own right.

In this article, we delve into the world of desoldering tools, exploring how a hot air gun compares to a solder sucker.

By examining their efficiency, technology, and pros and cons, we aim to provide valuable insights for those seeking freedom in choosing the right tool for their desoldering needs.

Key Takeaways

- Solder suckers are commonly used tools for removing soldered components and offer quick and accurate removal of excess solder.

- Desoldering braid and solder wick are alternative manual methods that are cost-effective and suitable for delicate electronics.

- Hot air guns are versatile tools that are suitable for larger components or extensive solder joints, but caution must be taken to avoid damaging nearby components.

- The choice of desoldering tool depends on factors such as skill level, type of component being removed, and personal preference.

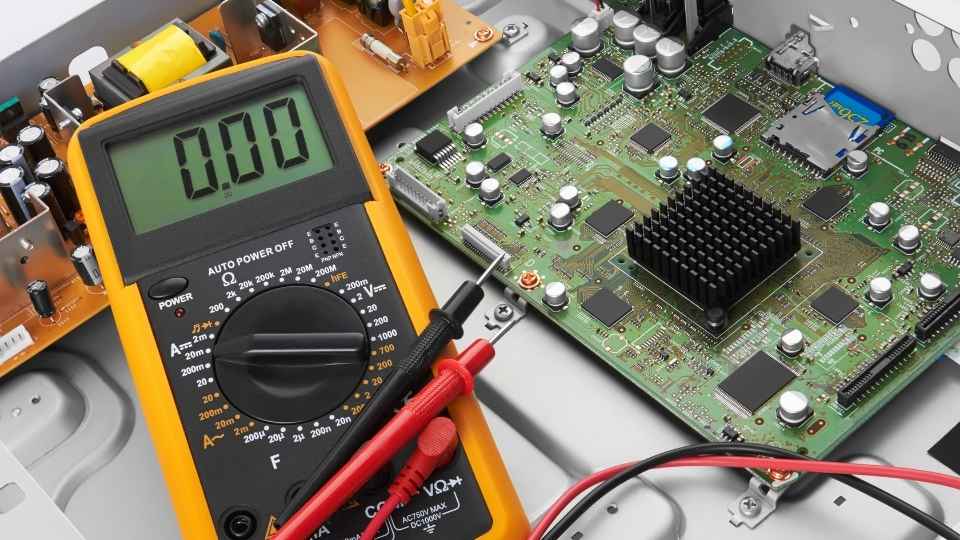

Desoldering tools are essential for removing soldered components. Understanding the basics of these tools is crucial for efficient and effective desoldering.

There are several types of desoldering tools available, each with its own advantages and applications. One commonly used tool is the solder sucker, which uses a vacuum to suck up molten solder from joints or pads.

Another popular option is the hot air gun. This tool delivers a stream of heated air to melt the solder and allow easy removal of components.

Both tools have their strengths and weaknesses, depending on factors such as the size and complexity of the project.

In this article, we will delve into the details of both desoldering methods, starting with understanding the solder sucker.

Understanding the Solder Sucker

The solder sucker is a desoldering tool commonly used in electronics repair and rework. It consists of a spring-loaded plunger attached to a hollow tube with a nozzle at the end. When heated, the solder melts and can be suctioned into the nozzle by pressing the plunger, creating a vacuum effect that removes unwanted solder from electronic components.

Understanding the solder sucker's effectiveness, pros and cons, as well as alternative desoldering methods, is crucial for efficient and successful desoldering operations.

Solder Sucker Effectiveness

When evaluating desoldering tools, it is important to assess the effectiveness of a solder sucker. A solder sucker is a handheld device that uses suction to remove excess solder from electronic components and circuit boards. Here are some key points to consider when evaluating the effectiveness of a solder sucker:

- Suction power: The strength of the suction determines how effectively the solder is removed.

- Tip size: A smaller tip allows for more precise targeting of specific areas.

- Ease of use: A user-friendly design makes it easier to operate and maneuver.

- Maintenance requirements: Some solder suckers require frequent cleaning or replacement of parts.

- Compatibility with different types of solders: It's important to ensure that the solder sucker can handle various types and sizes of solders.

Considering these factors will help you determine if a particular solder sucker meets your desoldering needs.

Now, let's explore the pros and cons of using a solder sucker.

Pros and Cons

One advantage of using a solder sucker is its ability to quickly and accurately remove excess solder from electronic components. The precision and efficiency of a solder sucker make it an indispensable tool for anyone working with electronics.

Unlike other desoldering methods, such as the hot air gun, the solder sucker offers more control over the removal process, ensuring minimal damage to delicate components.

With its ergonomic design and lightweight construction, the solder sucker allows for comfortable and easy handling during long periods of use. Additionally, the simplicity of operation makes it accessible to both professionals and hobbyists alike.

Its affordability adds to its appeal, making it an ideal choice for those seeking cost-effective solutions without compromising on performance.

Overall, the solder sucker stands out as an excellent option for efficient and accurate desoldering while providing freedom in terms of ease-of-use, accessibility, and cost-effectiveness.

Alternative Desoldering Methods

Alternatively, other methods for removing excess solder from electronic components include using a desoldering braid or employing a solder wick. These alternative methods offer certain advantages and disadvantages compared to hot air guns and solder suckers.

Here are five key points about these alternative desoldering methods:

Desoldering braid: This copper mesh is placed on the solder joint and heated with a soldering iron, allowing it to absorb the molten solder through capillary action.

Solder wick: Similar to the desoldering braid, but in the form of a thin copper wire coated with flux. It is used by pressing it against the joint and heating it with a soldering iron.

Precise control: Both the desoldering braid and solder wick allow for more precise removal of small amounts of solder, making them suitable for delicate electronics.

Manual operation: Unlike hot air guns and solder suckers, these methods require manual effort to remove the excess solder, which can be time-consuming.

Cost-effective: Desoldering braids and wicks are relatively inexpensive compared to hot air guns or high-quality solder suckers.

When choosing between these different desoldering methods, consider factors such as precision required, time constraints, and cost considerations.

Exploring the Power of Hot Air Guns

Hot air guns are versatile tools that generate a controlled stream of hot air, typically used in various applications such as shrinking heat shrink tubing, removing paint or varnish, and thawing frozen pipes. The power of hot air guns lies in their ability to deliver high temperatures quickly and precisely, making them an indispensable tool for professionals in industries such as electronics repair, automotive maintenance, and construction.

With adjustable temperature settings and interchangeable nozzles, hot air guns offer a wide range of benefits and applications for both DIY enthusiasts and professionals alike.

Hot Air Gun Benefits

A significant advantage of using a hot air gun for desoldering is its ability to evenly distribute heat, allowing for precise and controlled removal of solder joints. This makes it an ideal tool for various applications.

Here are some benefits of using a hot air gun:

Versatility: Hot air guns can be used not only for desoldering but also for shrinking heat shrink tubing, removing paint or varnish, and even thawing frozen pipes.

Adjustable temperature: Hot air guns often come with adjustable temperature settings, allowing users to customize the level of heat required for different tasks.

Quick heating time: These tools have fast heating elements that reach their maximum operating temperature within seconds, saving valuable time during projects.

No contact needed: Unlike solder suckers that require physical contact with the joint, hot air guns work by directing heated air onto the soldered area without touching it directly.

Portability: Hot air guns are compact and lightweight, making them easy to carry around and use in various locations.

With these advantages in mind, let's now explore the applications where hot air guns excel in desoldering and other tasks.

Applications for Hot Air

Hot air guns find extensive applications in various industries, making them a versatile tool for professionals seeking freedom in their work. One of the primary uses is in electronics, where hot air can be employed to remove and replace components on circuit boards. The controlled flow of hot air allows for precise heating and removal of solder, enabling the desoldering process without damaging delicate electronic components.

Additionally, hot air guns are used for shrink-wrapping applications by providing a consistent stream of heated air to shrink or seal materials together. This makes them invaluable in packaging and manufacturing industries, where efficiency and reliability are paramount.

Transitioning into the subsequent section about comparing the efficiency of solder wick and hot air guns, it is essential to evaluate both tools' effectiveness in different desoldering scenarios.

Comparing the Efficiency of Solder Wick and Hot Air Guns

When comparing the efficiency of desoldering tools, solder wick and hot air guns are often pitted against each other to determine which method is more effective. Both tools have their own advantages and limitations, making it important to understand their differences before choosing the right one for a specific task.

Here are five key points to consider when comparing solder wick and hot air guns:

Solder wick:

Effective for removing small amounts of solder.

Precise control over the desoldering process.

Can be used in tight spaces where a hot air gun may not reach.

Requires manual effort and skill to use effectively.

May leave some residue behind that needs additional cleaning.

Hot air gun:

Suitable for larger components or areas with extensive solder joints.

Rapid heating and cooling process increases efficiency.

Can remove multiple joints simultaneously.

Versatile tool that can also be used for other applications like shrink tubing or heat shrinking connectors.

Requires caution as excessive heat could damage nearby components.

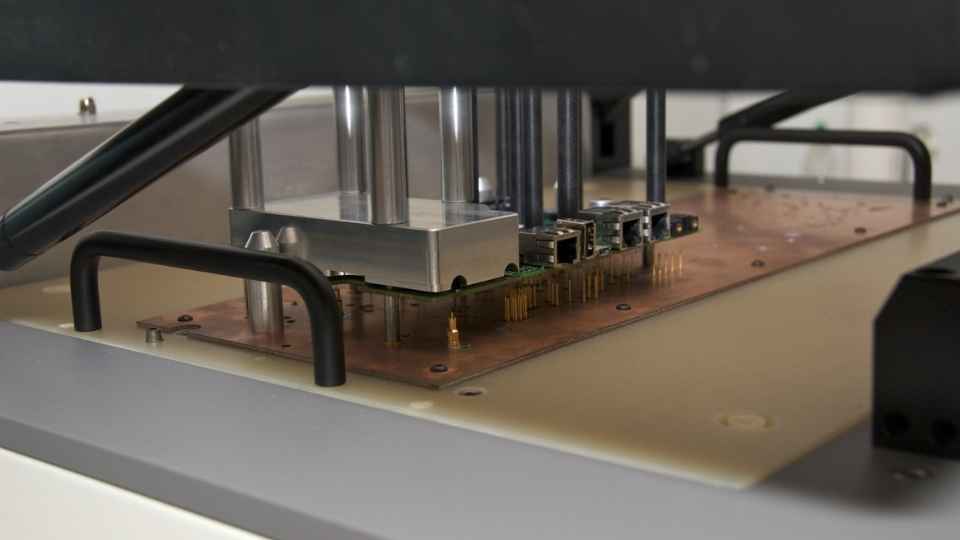

The Technology Behind Desoldering Stations

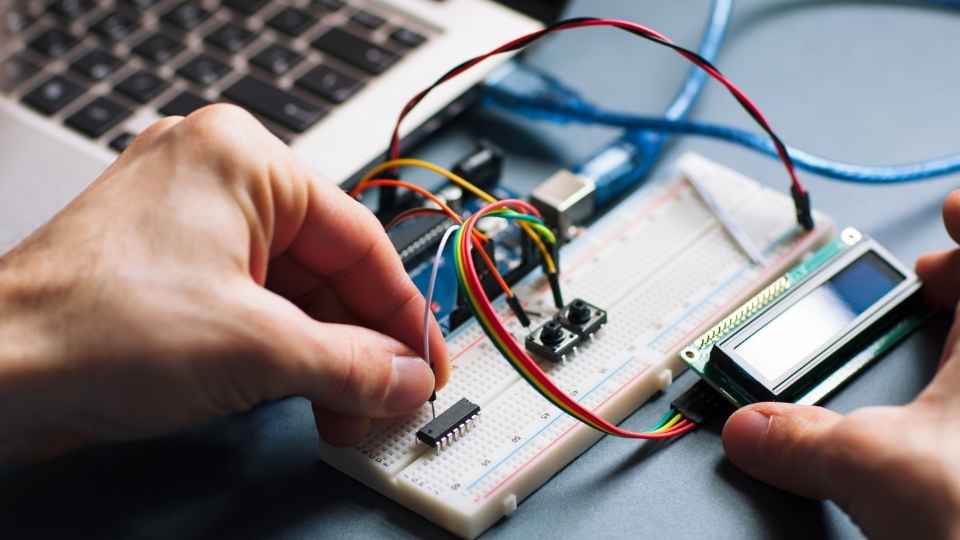

As we delve deeper into the world of desoldering tools, it is essential to understand the technology behind desoldering stations. These stations are designed to provide a controlled environment for effective and efficient desoldering operations.

Desoldering stations typically consist of three main components: a soldering iron, a vacuum pump or suction system, and temperature control circuitry. The soldering iron utilizes heat to melt the solder, while the vacuum pump or suction system removes the molten solder from the joint.

The temperature control circuitry plays a crucial role in maintaining optimal operating conditions. It ensures that the soldering iron reaches and maintains the desired temperature for efficient desoldering without causing damage to delicate components.

Moreover, modern desoldering stations often incorporate advanced features such as adjustable airflow and temperature settings, digital displays for precise monitoring, and automatic cooling functions.

The Role of Flux in the Desoldering Process

Flux plays a crucial role in facilitating the desoldering process by promoting solder flow, preventing oxidation, and enhancing wetting between the solder and the components.

Here are five key functions of flux in the desoldering process:

- Flux cleans the surfaces of both the component leads and the PCB pads, removing any dirt or oxide layers that may hinder proper solder flow.

- It helps to lower the surface tension of molten solder, allowing it to spread evenly across the joint and ensuring a strong bond.

- Flux also acts as a barrier against oxidation, preventing oxygen from reacting with the hot solder and forming detrimental oxides.

- By improving wetting properties, flux allows for better contact between the solder and component leads, resulting in improved electrical conductivity.

- Lastly, flux aids in heat transfer during reflow by conducting heat to ensure uniform heating across all joints.

Pros and Cons of Using a Hot Air Gun Vs. a Solder Sucker

When it comes to desoldering, two popular tools that are often used are the hot air gun and the solder sucker. Both these tools have their own pros and cons, which should be taken into consideration based on individual requirements.

The hot air gun utilizes heated air to melt the solder, making it easier to remove components from a circuit board. It provides versatility as it can be used for various tasks such as shrinking heat shrink tubing or reworking surface mount components. However, using a hot air gun requires skill and precision to avoid damaging nearby components or overheating sensitive parts.

On the other hand, a solder sucker is a vacuum-based tool specifically designed for desoldering. It offers precise control over the desoldering process and is generally considered safer than a hot air gun. However, it may struggle with removing larger or stubborn components due to its limited suction power.

Ultimately, the choice between a hot air gun and a solder sucker depends on factors like skill level, type of component being removed, and personal preference.

Frequently Asked Questions

There are various types of desoldering tools available in the market, including solder wick, desoldering pump, desoldering braid, hot air gun, and solder sucker. Each tool has its own advantages and is suitable for different applications.

Desoldering tools have a primary purpose of removing solder, but they can also be used for other tasks. Their versatility allows for various applications, making them essential in the electronics industry and beyond.

How Do Desoldering Stations Work and What Features Should One Look for When Purchasing One?

When considering a desoldering station, it is important to understand how it works and what features are essential. This includes temperature control, vacuum power, nozzle options, and compatibility with different types of solder joints.

When using desoldering tools, it is crucial to prioritize safety. Proper ventilation, protective eyewear, and following manufacturer instructions are necessary. Are you aware of the potential risks involved?

When using desoldering tools, it is important to avoid common mistakes such as applying excessive force, overheating the components, or not properly cleaning the solder joints. These errors can lead to damage or ineffective desoldering.

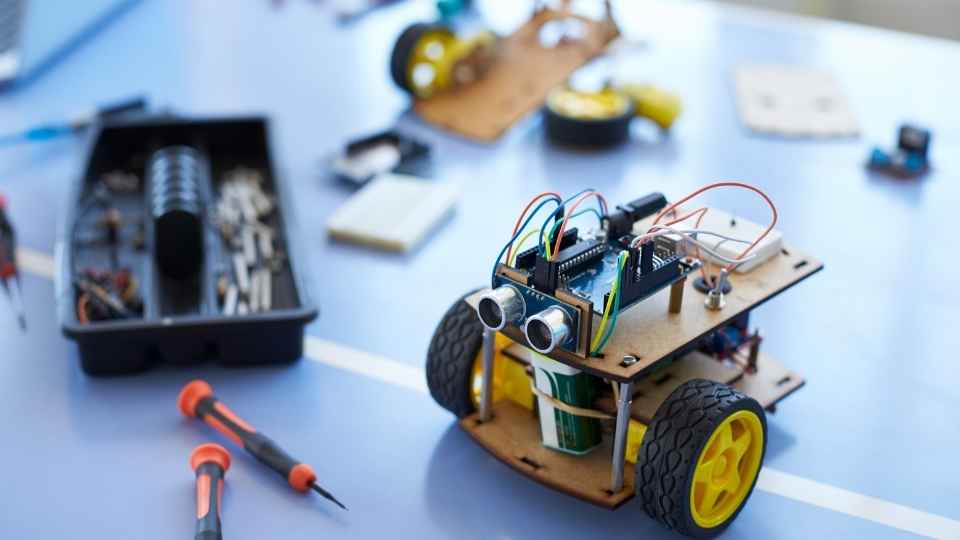

Basic Electronics ConceptsEssential ToolsCircuit Design BasicsMicrocontrollersDIY Electronics ProjectsRoboticsPrivacy PolicyTerms And Conditions

Basic Electronics ConceptsEssential ToolsCircuit Design BasicsMicrocontrollersDIY Electronics ProjectsRoboticsPrivacy PolicyTerms And Conditions