In the rapidly evolving field of semiconductor fabrication, nanoelectronics have emerged as a transformative force. They have revolutionized the way semiconductors are manufactured and pushed the boundaries of technological advancements. These nanoscale materials have opened up new possibilities for faster, smaller, and more efficient semiconductor devices. From enhancing computing power to enabling quantum computing, nanoelectronics have had a significant impact on the industry.

In this article, we delve into the impact of nanoelectronics on semiconductor fabrication. We explore both the challenges and opportunities that arise from their incorporation in this ever-evolving industry.

Key Takeaways

- Nanoelectronics revolutionized semiconductor manufacturing techniques, allowing for greater control and the production of smaller transistors.

- Nanoscale materials, such as graphene and nanoparticles, enhance semiconductor performance by improving device densities, operating speeds, and energy efficiency.

- Nanoelectronics advancements, including continual miniaturization and increased transistor performance, pave the way for quantum computing and push the limits of miniaturization and performance, impacting Moore's Law.

- Quantum computing has the potential to solve complex problems at an unprecedented scale through the use of qubits in superposition states, quantum algorithms, and quantum simulations. Integration of nanoelectronics with quantum systems improves overall system performance.

The Evolution of Semiconductor Fabrication Techniques

The evolution of semiconductor fabrication techniques has been driven by advancements in nanoelectronics, leading to the development of more efficient and precise methods for producing semiconductors.

Nanoelectronics, which deals with the manipulation and control of matter at the nanoscale, has revolutionized the field of semiconductor manufacturing.

Traditional methods involved using lithography techniques to pattern and etch materials to create transistors on a chip. However, as technology has advanced, scientists have turned to nanoelectronic approaches such as atomic layer deposition (ALD) and molecular beam epitaxy (MBE), which allow for greater control over material properties at the atomic level.

These techniques enable the production of ever smaller transistors with improved performance characteristics.

The impact of nanoelectronics on semiconductor manufacturing is profound, as it enables the development of faster, more energy-efficient devices that continue to drive technological innovation.

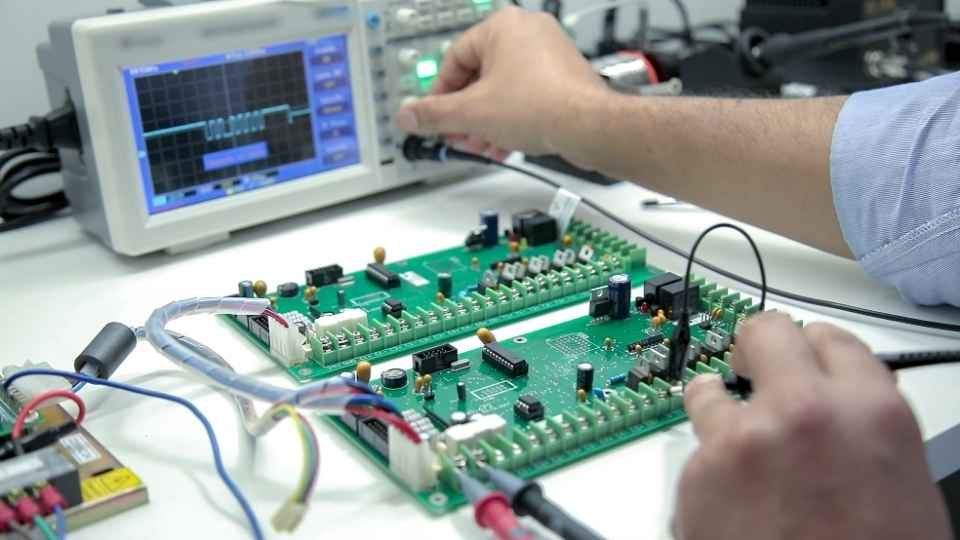

The Impact of Nanoelectronics on Semiconductor Manufacturing

One of the key aspects to consider when examining the impact of nanoelectronics on semiconductor manufacturing is how it has revolutionized the production processes and techniques utilized in the industry.

Nanoelectronics, which involve working with materials and devices at the nanoscale level, have brought about significant advancements in semiconductor fabrication.

Here are three ways nanoelectronics have reshaped this field:

Miniaturization: Nanoelectronics enable the creation of smaller and more efficient semiconductor components, leading to miniaturized devices that offer increased performance and functionality.

Enhanced Performance: The use of nanoscale materials and structures allows for improved electrical conductivity, reduced power consumption, and increased speed in semiconductor devices.

Novel Manufacturing Techniques: Nanoelectronic technologies have paved the way for innovative manufacturing methods such as atomic layer deposition (ALD) and electron beam lithography (EBL), enabling precise control over material properties and device characteristics.

Overall, nanoelectronics have had a profound impact on semiconductor manufacturing by pushing boundaries in terms of size reduction, performance enhancement, and manufacturing capabilities.

Exploring the Role of Nanoscale Materials in Semiconductor Fabrication

Nanoscale materials play a crucial role in revolutionizing the manufacturing processes and techniques employed in the semiconductor industry. These materials, which are typically less than 100 nanometers in size, have unique properties that can be harnessed to enhance the performance of semiconductor devices.

One such material is graphene, a single layer of carbon atoms arranged in a hexagonal lattice. Graphene exhibits exceptional electrical conductivity and mechanical strength, making it an ideal candidate for use in transistors and other electronic components. Additionally, nanoparticles made from materials like silicon or gold can be used as building blocks to create nanostructures with specific functionalities.

By incorporating nanoscale materials into semiconductor fabrication processes, manufacturers can achieve higher device densities, faster operating speeds, and improved energy efficiency.

This focus on nanoscale materials represents a significant shift from traditional semiconductor manufacturing methods and has paved the way for advancements in nanoelectronics. From Moore's Law predicting the doubling of transistor counts every two years to quantum computing promising unprecedented computational power, these developments highlight the incredible potential of nanoelectronics in shaping our technological future.

Advancements in Nanoelectronics: From Moore's Law to Quantum Computing

Advancements in nanoelectronics have played a crucial role in shaping the future of semiconductor technology. From the perspective of Moore's Law, nanoscale materials and techniques have allowed for the continual miniaturization and increased performance of transistors on integrated circuits.

Moreover, these advancements have also paved the way for quantum computing, which has the potential to revolutionize computation by harnessing quantum phenomena to perform complex calculations at an unprecedented scale.

Impact on Moore's Law

The impact of nanoelectronics on semiconductor fabrication is evident in the evolving landscape of Moore's Law. Nanoelectronics, which deals with devices and materials at the nanoscale level, has allowed for significant advancements in semiconductor technology, pushing the limits of miniaturization and performance.

Here are three key ways in which nanoelectronics have reshaped semiconductor fabrication:

Shrinking transistor sizes: Nanoelectronics has enabled the production of smaller and more efficient transistors, leading to increased processing power and improved energy efficiency.

Enhanced functionality: With nanoscale manufacturing techniques, semiconductors can now incorporate a greater number of components onto a single chip, resulting in enhanced functionality and capabilities.

Increased integration density: The use of nanoelectronic materials allows for higher integration density on chips, enabling more complex circuits to be packed into smaller areas.

These advancements paved the way for further exploration into quantum computing potential...

Quantum Computing Potential

Quantum computing potential holds promise for revolutionizing computational power and solving complex problems at an unprecedented scale. Quantum computers leverage the principles of quantum mechanics to perform calculations that are currently beyond the capabilities of classical computers. Unlike classical bits, which can represent either a 0 or a 1, quantum bits, or qubits, can exist in superposition states that allow them to represent both 0 and 1 simultaneously. This inherent parallelism gives quantum computers the ability to solve certain problems exponentially faster than their classical counterparts.

One of the main applications of quantum computing lies in optimization and simulation tasks. Quantum algorithms have the potential to find optimal solutions for complex optimization problems more efficiently than classical algorithms. Additionally, quantum simulations could provide valuable insights into chemical reactions, material properties, and other phenomena that are difficult to study using classical methods alone.

As we explore further advancements in nanoelectronics in chip design, it is important to consider how these developments can be harnessed alongside quantum computing technologies. The integration of nanoscale devices with quantum systems has the potential to enable higher-speed communication between components and improve overall system performance.

Nanoelectronics in Chip Design

As technology continues to advance, the incorporation of nanoelectronics into chip design is becoming increasingly significant. Nanoelectronics, which involves the manipulation of materials and devices at the nanoscale level, has opened up new possibilities for semiconductor fabrication.

Here are three key ways in which nanoelectronics are reshaping chip design:

Increased performance: Nanoelectronics enable the creation of smaller and more efficient transistors, leading to higher performance chips with faster processing speeds.

Energy efficiency: By utilizing nanomaterials and novel device architectures, nanoelectronics allow for the development of low-power chips that consume less energy while maintaining high performance levels.

Integration of diverse functionalities: Nanoscale components can be easily integrated into a single chip, enabling the integration of various functionalities such as sensors, memory elements, and processors onto a single platform.

The incorporation of nanoelectronics into chip design not only enhances performance but also paves the way for future innovations in areas like wearable technology, internet of things (IoT), and artificial intelligence (AI).

With continued advancements in nanotechnology, we can expect even more groundbreaking developments in semiconductor fabrication.

The Challenges and Opportunities of Incorporating Nanoelectronics in Semiconductor Manufacturing

The incorporation of nanoelectronics in semiconductor manufacturing presents both challenges and opportunities.

On one hand, the miniaturization and increased functionality of nanoscale devices offer immense potential for improving performance and efficiency.

However, the fabrication processes required to produce these nanoscale devices at a large scale pose significant challenges due to factors such as yield rates, compatibility with existing technologies, and cost-effectiveness.

Nanoelectronics: Game Changer or Hype

Nanoelectronics, with its potential to revolutionize semiconductor fabrication, is a topic that prompts intense debate about whether it is a game changer or merely hype. Here are three key points to consider:

Miniaturization: Nanoelectronics allows for the development of smaller and more efficient devices. By harnessing the unique properties of nanomaterials, such as quantum confinement and surface effects, researchers can create transistors and other components at the nanoscale.

Enhanced Performance: The use of nanotechnology in semiconductor manufacturing offers the promise of improved performance in terms of speed, power consumption, and functionality. Nanoscale devices have the potential to outperform their traditional counterparts by leveraging quantum mechanics principles.

New Possibilities: Nanoelectronics opens up new avenues for innovation and technological breakthroughs. It enables advancements in areas such as flexible electronics, wearable devices, energy harvesting systems, and biomedical applications.

As we delve deeper into the realm of nanoelectronics, it becomes evident that overcoming manufacturing scale challenges will be crucial in realizing its full potential.

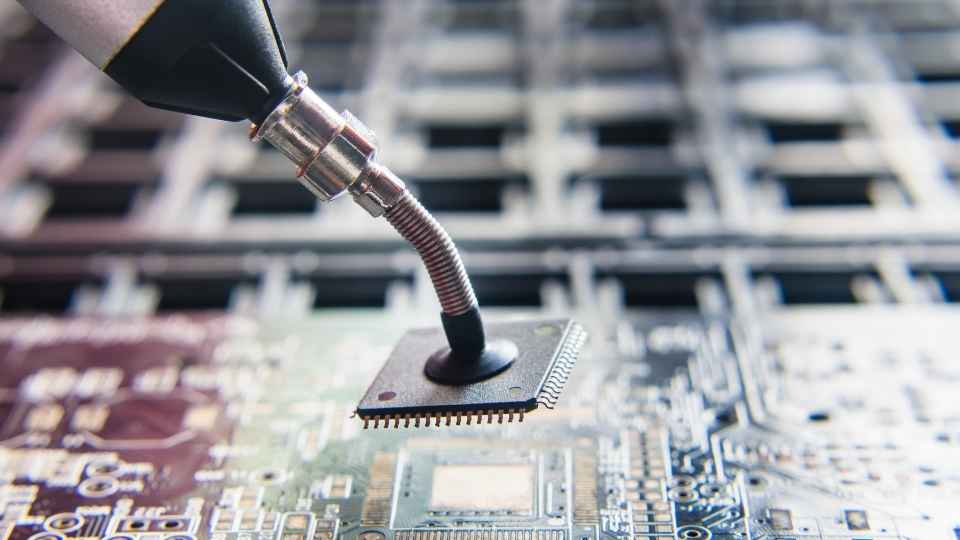

Overcoming Manufacturing Scale Challenges

To fully harness the potential of nanoelectronics, it is imperative to address and overcome the challenges associated with scaling up manufacturing processes. Nanoelectronics, with their ability to operate at an atomic or molecular scale, offer unprecedented possibilities for advancements in various industries. However, translating these possibilities into tangible products requires a robust and efficient manufacturing process.

One major challenge in scaling up nanoelectronic manufacturing is maintaining high precision while increasing production volume. Traditional fabrication techniques struggle to maintain the required accuracy when dealing with such small structures. Additionally, ensuring uniformity across a large number of devices becomes increasingly difficult as the size decreases.

Another challenge lies in cost-effectiveness. The investment required for specialized equipment and materials needed for nanoscale fabrication can be significant, making mass production economically unfeasible for some applications.

Overcoming these challenges necessitates innovations in manufacturing techniques and materials that can deliver both precision and scalability without compromising cost efficiency. Research efforts are focused on developing novel methods such as bottom-up assembly approaches and new materials like graphene that offer promise in addressing these obstacles.

Harnessing Nanoelectronics for Faster, Smaller, and More Efficient Semiconductor Devices

By harnessing the potential of nanoelectronics, semiconductor fabrication is experiencing significant advancements in terms of faster speeds, smaller sizes, and increased efficiency.

Nanoelectronics refers to the manipulation and control of matter at the nanoscale level, typically involving dimensions less than 100 nanometers. This technology has revolutionized semiconductor fabrication by enabling the development of devices with enhanced performance and capabilities.

Faster speeds: Nanoelectronics allows for the creation of transistors and other components that operate at higher frequencies, resulting in faster processing speeds for electronic devices.

Smaller sizes: By utilizing nanoscale materials and structures, semiconductor manufacturers can create smaller and more compact devices without compromising their functionality.

Increased efficiency: Nanoelectronic devices offer improved energy efficiency due to reduced power consumption and better heat dissipation.

These advancements in nanoelectronics are driving innovation in various industries such as telecommunications, computing, healthcare, and renewable energy. As a result, consumers can enjoy cutting-edge technologies that provide them with greater freedom in their daily lives.

Frequently Asked Questions

What Are the Main Challenges Faced in Incorporating Nanoelectronics Into Semiconductor Manufacturing?

The main challenges faced in incorporating nanoelectronics into semiconductor manufacturing include issues related to scalability, reliability, and compatibility with existing processes. These challenges require innovative solutions and collaboration between researchers, engineers, and industry stakeholders.

The use of nanoscale materials in semiconductor devices has a profound impact on their performance and functionality. These materials enable faster processing speeds, increased energy efficiency, and enhanced device miniaturization, revolutionizing the field of semiconductor fabrication.

Can You Explain the Concept of Moore's Law and Its Relevance to Advancements in Nanoelectronics?

Moore's Law is a principle that states the number of transistors on a microchip doubles approximately every two years, leading to exponential growth in computational power. In the context of nanoelectronics, Moore's Law remains relevant as it drives advancements in semiconductor fabrication and enables the miniaturization of electronic devices.

What Are the Potential Applications of Quantum Computing in the Field of Nanoelectronics?

The potential applications of quantum computing in the field of nanoelectronics include improved optimization algorithms for semiconductor fabrication processes, enabling more precise control over material properties and device performance.

How Do Nanoelectronics Contribute to the Development of Faster, Smaller, and More Efficient Semiconductor Devices?

Nanoelectronics play a crucial role in advancing semiconductor devices by enabling faster, smaller, and more efficient designs. Through the use of nanoscale components and materials, they enhance performance and enable new functionalities in various applications.

Basic Electronics ConceptsEssential ToolsCircuit Design BasicsMicrocontrollersDIY Electronics ProjectsRoboticsPrivacy PolicyTerms And Conditions

Basic Electronics ConceptsEssential ToolsCircuit Design BasicsMicrocontrollersDIY Electronics ProjectsRoboticsPrivacy PolicyTerms And Conditions