In the world of soldering, precision and safety are paramount. Like a skilled artist with their palette, a soldering technician requires the right tools to create masterpieces. Enter the soldering station: the ultimate instrument for controlled heat and efficient fume extraction.

But are adjustable temperature and fume extractors truly necessary? In this article, we delve into the technicalities of soldering stations, exploring key features, benefits of adjustable temperature control, and the role of fume extractors in creating a safe working environment.

Join us as we uncover the best soldering stations for your needs.

Key Takeaways

- Adjustable temperature control is essential for precise regulation and optimal heat transfer, ensuring strong and reliable solder joints while preventing damage from excessive heat.

- Fume extractors play a crucial role in creating a safe soldering environment by removing hazardous fumes and pollutants, protecting workers' health, reducing fire hazards, and enhancing productivity.

- Compliance with safety regulations is important for preventing health hazards, protecting individuals from respiratory problems, and extending the lifespan of soldering equipment and electronic components.

- The use of a high-quality soldering station with features such as digital temperature display, quick heat-up time, good thermal recovery, and durable construction is crucial for achieving optimal soldering results and increasing productivity.

Key Features to Look for in a Soldering Station

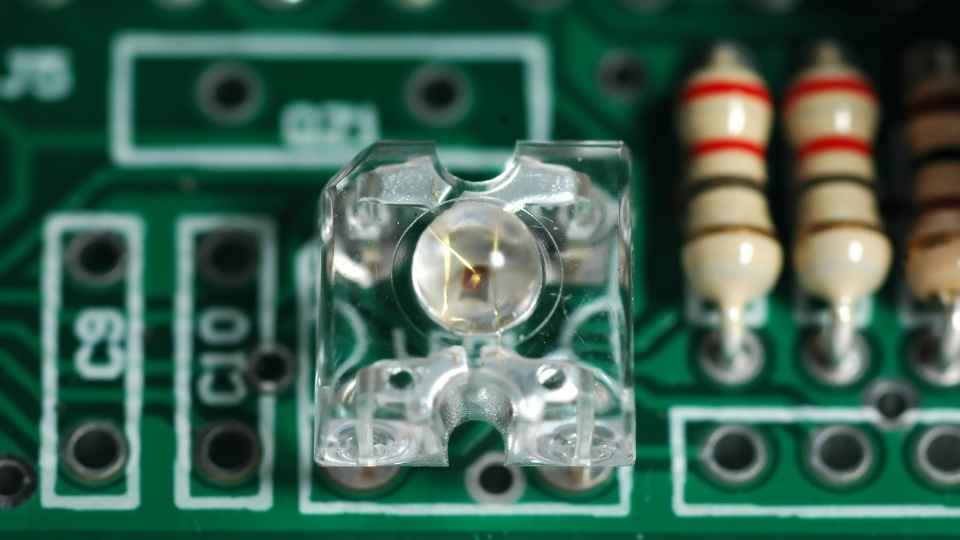

When searching for a soldering station, it is important to consider key features that can greatly enhance the overall functionality and efficiency of the device.

One crucial feature to look for is a digital temperature display. This allows precise control over the soldering iron's temperature, ensuring optimal performance and preventing damage to sensitive components.

Additionally, a soldering station with adjustable temperature settings provides freedom to work with various types of materials and projects.

Another essential feature is quick heat-up time. A soldering station that heats up rapidly saves valuable time and increases productivity in demanding situations.

Lastly, it is imperative to choose a soldering station with good thermal recovery. This ensures consistent performance even after prolonged use or when working on large-scale projects.

Considering these features will lead to selecting a high-quality soldering station that meets all your needs.

Moving forward, let's discuss the importance of adjustable temperature control in more detail...

The Importance of Adjustable Temperature Control

Adjustable temperature control is a crucial feature in soldering stations as it allows for precise regulation of the soldering temperature. This level of control ensures that the solder melts at the optimal temperature, resulting in strong and reliable joints.

Additionally, adjustable temperature control provides flexibility to work with different types of materials and components, preventing damage caused by excessive heat.

Optimal Soldering Temperature

The optimal temperature for soldering is crucial to ensure proper bonding and avoid damaging electronic components. When soldering, it is important to consider the melting point of the solder alloy being used. Most commonly used solders have a melting point range between 180°C and 190°C (356°F and 374°F). However, it is essential to note that different electronic components may have specific temperature requirements for their soldering process.

Excessive heat can damage delicate components, causing them to malfunction or even fail completely. On the other hand, insufficient heat can result in weak joints that may break or cause intermittent connections.

To determine the optimal temperature for your specific application, consult the datasheets or technical specifications provided by component manufacturers. It is also recommended to perform trial runs on scrap materials before engaging in actual work.

Temperature Control Benefits

Temperature control is a critical factor in ensuring consistent and high-quality soldering results. Proper temperature control offers numerous benefits that contribute to the overall success of soldering operations. Here are some key advantages:

- Stability: Maintaining a stable temperature prevents fluctuations that can lead to poor solder joint quality.

- Precision: Adjustable temperature settings allow for precise control, ensuring optimal heat transfer and avoiding damage to sensitive components.

- Versatility: Different soldering tasks require different temperatures, and adjustable controls enable technicians to accommodate various requirements.

- Efficiency: A regulated temperature reduces the time required for soldering, increasing productivity.

- Reliability: Consistent temperature control ensures reliable connections and decreases the risk of cold joints or other solder defects.

Adjustable Vs Fixed Temperature?

One key consideration when comparing adjustable and fixed temperature options is the level of precision required for a particular soldering task.

Adjustable temperature soldering stations offer the freedom to finely tune the temperature settings, allowing for greater control over the soldering process. This is especially important when working with delicate components or intricate circuitry that require precise heat application.

On the other hand, fixed temperature options provide a simpler and more streamlined approach, eliminating the need for constant adjustments. This can be advantageous for repetitive tasks or when time efficiency is crucial.

Ultimately, the choice between adjustable and fixed temperature depends on individual preferences and specific project requirements. Having the freedom to select either option provides flexibility and ensures that every soldering task can be accomplished with optimal precision and efficiency.

It is imperative to consider the necessity of a fume extractor when evaluating soldering stations for optimal workplace safety and air quality. Soldering processes generate harmful fumes that, if not properly controlled, can pose serious health risks. Here are five reasons why a fume extractor should be an essential component of your soldering station:

Ensures clean air by removing hazardous fumes and pollutants

Protects the health of workers from potential respiratory issues

Prevents long-term exposure to toxic substances present in solder smoke

Reduces the risk of fire hazards caused by accumulated fumes

Creates a comfortable working environment, increasing productivity

By investing in a soldering station with a built-in or standalone fume extractor, you prioritize the well-being of yourself and your team while maintaining compliance with safety regulations.

Now let's delve into other factors to consider when choosing the ideal soldering station for your needs.

Factors to Consider When Choosing a Soldering Station

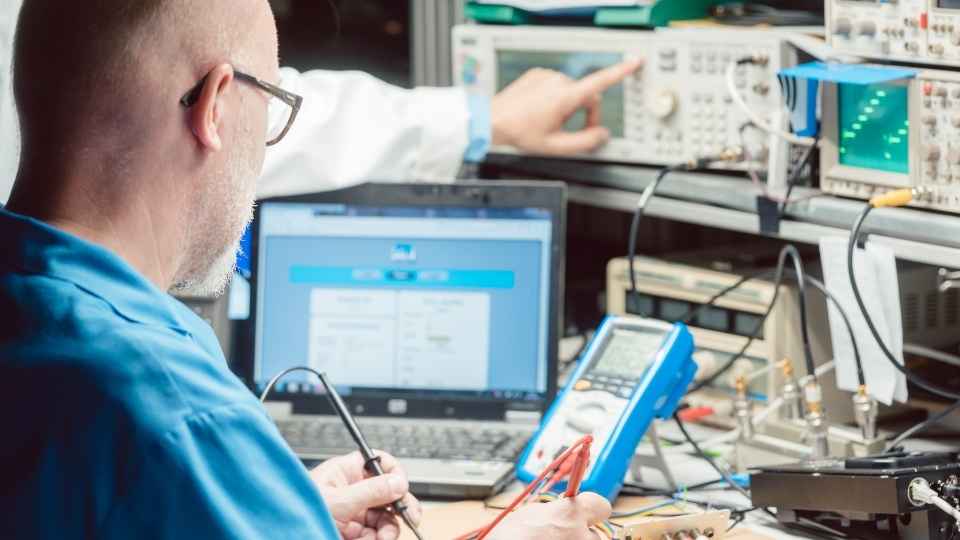

When selecting a soldering station, it is important to carefully consider factors such as wattage, tip compatibility, and ergonomic design to ensure optimal performance and user comfort.

Wattage determines the heating power of the station, with higher wattages being able to heat up faster and maintain stable temperatures during prolonged use.

Tip compatibility is crucial as different tasks require different types of tips, such as chisel or conical tips.

An ergonomic design ensures that the soldering station is comfortable to use for extended periods without causing strain or fatigue.

Additionally, features like adjustable temperature control allow users to precisely set the temperature according to their specific needs.

These considerations are key in choosing a soldering station that provides freedom and flexibility in achieving high-quality soldering results efficiently and comfortably.

The Benefits of Adjustable Temperature for Different Soldering Applications

The ability to precisely control temperature settings is advantageous for various soldering applications, as it allows for optimal heat management and ensures the integrity of delicate electronic components. Adjustable temperature soldering stations offer a range of benefits, including:

Enhanced precision: The ability to fine-tune temperature settings enables technicians to match the specific requirements of different soldering tasks.

Component protection: Delicate electronic components can be damaged by excessive heat. Adjustable temperature allows technicians to work within safe temperature ranges, minimizing the risk of component damage.

Versatility: Different solder alloys require different temperatures for optimal performance. Adjustable temperature soldering stations provide flexibility to work with various types of solders.

Process optimization: Some soldering applications may require specific temperature profiles to achieve desired results. With adjustable temperature settings, technicians can easily customize their processes accordingly.

Longevity: By avoiding overheating or underheating, adjustable temperature control helps extend the lifespan of both the soldering equipment and the electronic components being worked on.

Overall, having precise control over temperature settings is essential for successful and efficient soldering operations in a variety of applications.

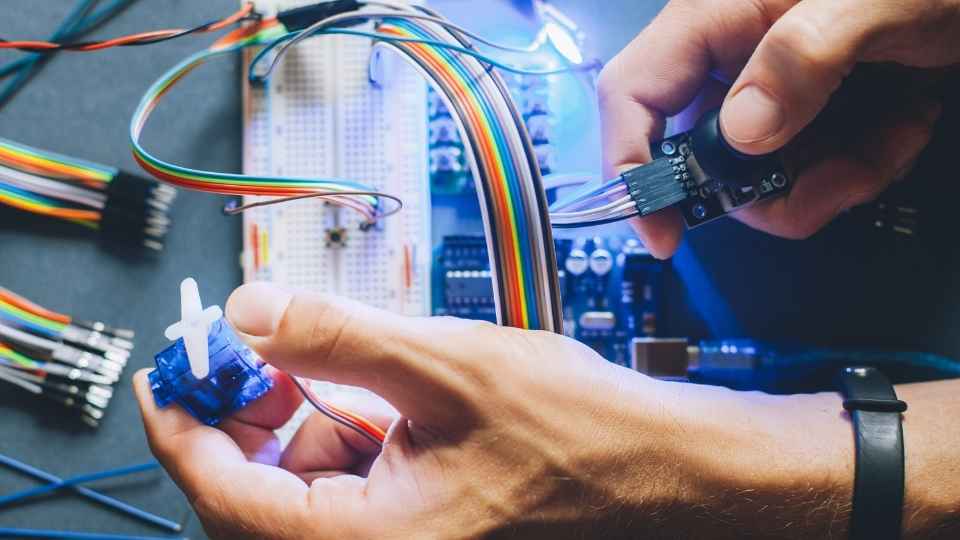

In addition to adjustable temperature, another crucial component in creating a safe soldering environment is the use of fume extractors. These devices play a vital role in removing harmful fumes and gases generated during the soldering process.

Fume extractors work by capturing the contaminants at their source, preventing them from spreading into the surrounding air. They typically consist of a fan or suction mechanism that draws the fumes through a filter system designed to capture and remove harmful particles.

The benefits of using fume extractors are twofold: protecting the health and safety of individuals working with soldering equipment and maintaining an overall clean workspace. By effectively removing fumes, these devices reduce the risk of respiratory problems and exposure to hazardous substances.

Investing in high-quality fume extractors ensures compliance with safety regulations while providing freedom for individuals to work without worrying about potential health hazards associated with soldering activities.

Frequently Asked Questions

What Are Some Alternative Options for Temperature Control in Soldering Stations?

Some alternative options for temperature control in soldering stations include digital temperature controllers, manual temperature adjustment knobs, and programmable presets. These options provide flexibility and precision in regulating the soldering temperature according to specific requirements.

How Do Adjustable Temperature Settings Affect the Quality of Soldering Joints?

Adjustable temperature settings play a crucial role in determining the quality of soldering joints. By allowing precise control over the temperature, soldering stations equipped with this feature ensure optimal heat transfer and minimize the risk of damage to delicate components or insufficient bonding.

A fume extractor can be used for various purposes beyond soldering, as it effectively removes harmful particles and gases from the air. Its versatility makes it a valuable tool in industries such as welding, electronics manufacturing, and chemical laboratories.

Using a soldering station without a fume extractor can pose potential health risks. Without proper ventilation, harmful fumes and particles can be inhaled, leading to respiratory issues and other health complications.

When using a soldering station with a fume extractor, it is important to consider additional safety measures. These may include wearing appropriate personal protective equipment, ensuring proper ventilation in the workspace, and following manufacturer guidelines for safe usage.

Basic Electronics ConceptsEssential ToolsCircuit Design BasicsMicrocontrollersDIY Electronics ProjectsRoboticsPrivacy PolicyTerms And Conditions

Basic Electronics ConceptsEssential ToolsCircuit Design BasicsMicrocontrollersDIY Electronics ProjectsRoboticsPrivacy PolicyTerms And Conditions