In a world where electronics have become an integral part of our lives, it is crucial to prioritize safety when working with these devices. From understanding electrical hazards to adopting best practices for handling components, this article aims to equip beginners with essential electronics safety tips.

By following these guidelines, you can protect yourself and prevent accidents while delving into the world of DIY electronics. So, let's dive in and explore the necessary precautions and measures that will ensure your journey into this exciting field remains secure and enjoyable.

Key Takeaways

- Electric shock can result from direct contact with live wires or faulty equipment, causing severe injuries or death.

- Safety measures such as wearing insulated gloves and footwear can help mitigate risks.

- Components should be inserted and removed gently to prevent bending pins or damaging connectors.

- Grounding yourself before handling electronic components discharges built-up static electricity.

Understanding the Risks: Electrical Hazards and Safety Precautions

Understanding the risks associated with electrical hazards is essential in order to implement appropriate safety precautions. Electrical hazards pose a significant threat to individuals and property, making it crucial for beginners in electronics to be well-informed about these dangers.

One of the primary risks is electric shock, which can result from direct contact with live wires or faulty equipment. This can lead to severe injuries or even death.

Another risk is fire caused by short circuits, overloading of circuits, or improper wiring practices.

In addition to these dangers, there is also the potential for explosions if electrical equipment comes into contact with flammable materials.

To mitigate these risks, beginners should prioritize safety measures such as wearing insulated gloves and footwear, using circuit breakers and fuses, proper grounding techniques, regular inspection and maintenance of electrical systems, and following established safety standards and guidelines provided by regulatory bodies such as OSHA (Occupational Safety and Health Administration).

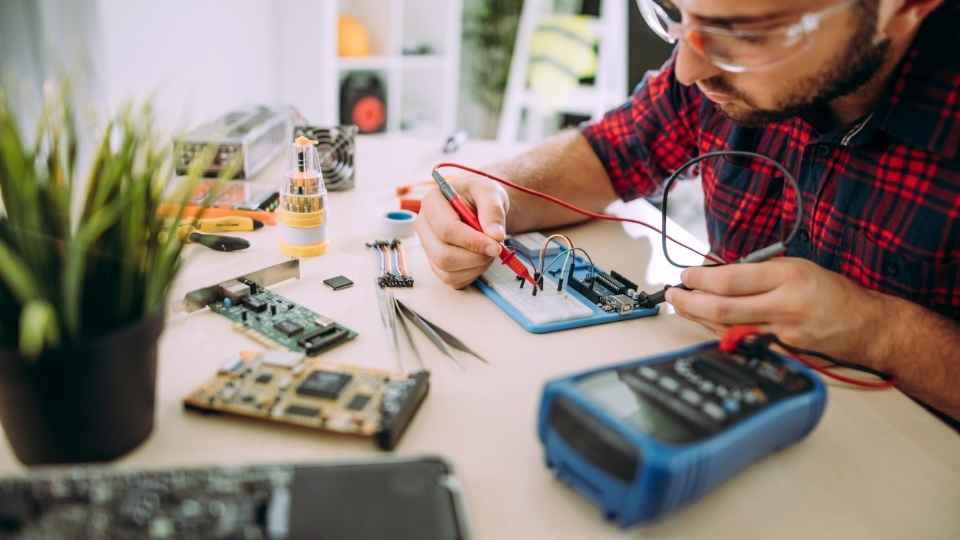

Handling Electronic Components: Best Practices and Safety Measures

When it comes to handling electronic components, following best practices and safety measures is crucial to avoid damage and ensure optimal performance.

Proper component storage methods, such as using anti-static bags or containers, can help prevent static discharge that could harm sensitive electronics.

Additionally, safe handling techniques, like wearing anti-static gloves and grounding yourself before touching components, further minimize the risk of electrical damage.

Component Storage Methods

To ensure the longevity and proper functioning of electronic components, it is crucial to implement effective storage methods. Proper storage not only protects the components from physical damage but also prevents exposure to environmental factors that can degrade their performance.

When storing electronic components, it is important to keep them in a clean and dry environment with controlled temperature and humidity levels. Components should be stored in anti-static bags or containers to prevent static electricity buildup, which can cause damage.

Additionally, organizing components in labeled containers or bins can facilitate easy retrieval when needed. By investing time and effort into implementing proper storage methods, beginners can safeguard their electronic components and maximize their lifespan.

Now that we understand the importance of component storage, let's move on to another critical aspect of electronics safety: avoiding static discharge.

Avoiding Static Discharge

One effective way to prevent damage to electronic components is by implementing proper measures to avoid static discharge. Static electricity can cause significant harm to sensitive electronics, leading to malfunctions or complete failure. To ensure the safety of your components, follow these essential tips:

Ground yourself: Before handling any electronic component, make sure you discharge any built-up static electricity by touching a grounded object or using an anti-static wrist strap.

Use anti-static packaging: When storing or transporting electronic components, utilize anti-static bags or containers to protect them from potential static buildup.

Work in an ESD-safe environment: Set up your workspace with an electrostatic discharge (ESD) mat and grounded work surface to minimize the risk of static electricity damaging your components.

Avoid common sources of static discharge: Stay away from carpeted areas, wear clothing made of natural fibers instead of synthetic materials, and keep pets away from your workspace as they can generate static electricity.

Safe Handling Techniques

Implementing proper handling techniques is crucial for ensuring the safe and effective use of electronic components.

When working with electronic devices, it is important to follow certain safety guidelines to prevent damage or injury. Firstly, always handle electronic components with clean hands to avoid contaminating them with oils or dirt.

Additionally, ensure that you are properly grounded by wearing an anti-static wrist strap or regularly touching a grounded metal object to discharge any static electricity.

When inserting or removing components, do so gently and carefully to avoid bending pins or damaging connectors.

Furthermore, it is advisable to store unused components in anti-static bags to protect them from electrostatic discharge.

Protecting Against Static Electricity: Tips for Anti-Static Safety

When working with electronic components, it is crucial to protect against static electricity as it can cause damage to sensitive devices.

To ensure anti-static safety, the use of anti-static wristbands is necessary to discharge any built-up static charge in the body.

Additionally, adopting proper cleaning methods and taking precautions to prevent electrostatic discharge can further minimize the risk of damaging electronic components.

Anti-Static Wristbands Necessary

Wearing an anti-static wristband is crucial for ensuring the safety of both the electronics and the individual handling them. Static electricity can cause damage to sensitive electronic components, leading to costly repairs or even complete failure. By wearing an anti-static wristband, you can effectively eliminate the risk of static discharge during electronic assembly or repair tasks.

Here are four reasons why wearing an anti-static wristband is necessary:

Prevents Electrostatic Discharge (ESD): An anti-static wristband safely channels static electricity away from your body and into a grounding system, preventing ESD from damaging electronics.

Protects Sensitive Components: Electronics such as computer chips or circuit boards are extremely sensitive to static electricity. Wearing a wristband ensures that these components remain safe and undamaged.

Ensures Personal Safety: In addition to protecting electronics, an anti-static wristband also safeguards the user from potential harm caused by electric shocks.

Easy to Use: Anti-static wristbands are simple to wear and require no technical expertise. They provide peace of mind while working with delicate electronic equipment.

Best Anti-Static Cleaning Methods

To effectively clean electronic devices and prevent static buildup, it is important to follow proper anti-static cleaning methods. Dust and debris can accumulate on electronic surfaces, leading to poor performance and potential damage.

To avoid this, start by turning off the device and unplugging it from any power source. Use a soft, lint-free cloth or a microfiber cloth to gently wipe the surface of the device. Avoid using abrasive materials that could scratch or damage the screen or casing.

For hard-to-reach areas or stubborn dirt, use compressed air or an anti-static brush to remove debris without causing harm. It's essential to handle electronic devices with care during cleaning to avoid accidental drops or mishandling.

How to Prevent Electrostatic Discharge?

One effective method for preventing electrostatic discharge is to properly ground yourself and the electronic device before handling it. This ensures that any static electricity you may have accumulated is safely discharged, protecting both you and the device from potential damage.

Here are four essential steps to prevent electrostatic discharge:

Wear an anti-static wrist strap: This strap connects your body to a grounded object, allowing any built-up static charge to be safely released.

Use an anti-static mat: Placing your electronic device on an anti-static mat provides a conductive surface that dissipates any static charges.

Keep moisture levels in check: Dry environments increase the likelihood of electrostatic discharge, so consider using a humidifier when working with electronics.

Avoid wearing synthetic clothing: Synthetic materials generate more static electricity than natural fibers, so opt for cotton or wool garments instead.

Safe Soldering Techniques: Guidelines for Beginners

When soldering electronic components, it is crucial to adhere to safe techniques in order to minimize the risk of accidents or damage. Here are some guidelines for beginners to ensure safe soldering practices.

- Always work in a well-ventilated area to avoid inhaling toxic fumes released during the soldering process.

- Wear safety glasses and heat-resistant gloves to protect your eyes and hands from potential injuries or burns.

Before starting:

- Make sure the soldering iron is properly grounded.

- Never touch the hot tip of the soldering iron with bare hands.

- Use a suitable temperature setting for your soldering iron.

- Avoid applying excessive heat as it can damage delicate components or cause them to come loose.

Finally, remember to:

- Unplug the soldering iron when not in use.

- Store it safely away from flammable materials.

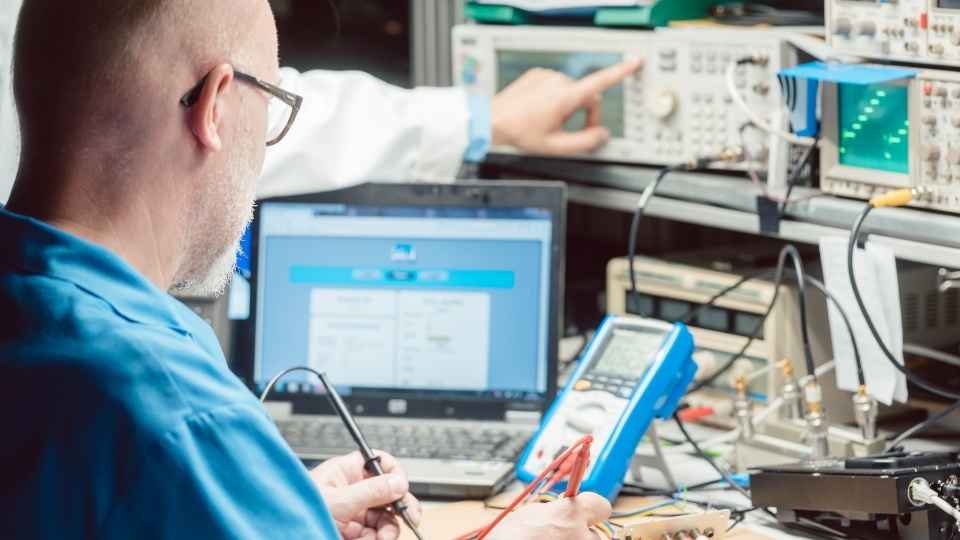

Essential Safety Equipment for Electronics Work

Adhering to proper safety protocols while working with electronic components requires the use of essential equipment. These items not only protect you from potential hazards but also ensure that your work is carried out efficiently and effectively.

Here are four essential safety equipment for electronics work:

Safety Glasses: Protect your eyes from sparks, debris, and harmful substances during soldering or any other electronic tasks.

Heat-Resistant Gloves: Shield your hands from burns when handling hot components or using heat-generating tools like soldering irons.

Properly Grounded Soldering Iron: Prevent electrical shocks by using a soldering iron that is properly grounded to avoid any unwanted current flow.

ESD Protection Mat and Wrist Strap: Minimize electrostatic discharge (ESD) risks by using an ESD mat and wrist strap to protect sensitive electronic components.

Maintaining a Safe Working Environment: Organization and Cleanliness

Maintaining a safe working environment for electronics projects requires maintaining organization and cleanliness throughout the workspace. An organized and clean workspace not only improves efficiency but also reduces the risk of accidents or damage to equipment.

Start by designating specific areas for different tasks, such as soldering, testing, and storage. This helps prevent tools and materials from becoming misplaced or cluttered.

Additionally, ensure that all cables and cords are neatly arranged and free from tangles to avoid tripping hazards.

Regularly clean your workspace to remove dust, debris, and excess solder flux that can accumulate over time. Use appropriate cleaning supplies and techniques to prevent damage to delicate electronic components.

Frequently Asked Questions

What Are the Common Electrical Hazards to Be Aware of When Working With Electronics?

Common electrical hazards to be aware of when working with electronics include electric shock, short circuits, overheating, and fire. It is important to follow safety guidelines, such as using insulated tools and avoiding water near electrical equipment, to minimize these risks.

How Can I Prevent Damage to Electronic Components When Handling Them?

To prevent damage to electronic components when handling them, it is crucial to observe proper static electricity precautions, use ESD-safe tools and work on an anti-static mat or surface. These measures ensure the safety and integrity of the components.

What Are the Potential Risks of Static Electricity and How Can I Protect Against It?

Static electricity poses potential risks to electronic components, including damage and malfunction. To protect against it, beginners should ground themselves by touching a metal object before handling electronics and use anti-static wristbands or mats during assembly or repair.

Are There Any Specific Safety Guidelines to Follow When Soldering for Beginners?

When soldering for beginners, it is crucial to follow specific safety guidelines. These include wearing protective equipment like safety goggles and gloves, working in a well-ventilated area, and ensuring the proper handling of hot soldering irons and materials.

What Safety Equipment Is Necessary for Working With Electronics and Why Is It Important?

Safety equipment such as safety goggles, gloves, and a fire extinguisher are necessary when working with electronics. This is important to protect oneself from potential hazards like electrical shocks, burns, and fires.

Basic Electronics ConceptsEssential ToolsCircuit Design BasicsMicrocontrollersDIY Electronics ProjectsRoboticsPrivacy PolicyTerms And Conditions

Basic Electronics ConceptsEssential ToolsCircuit Design BasicsMicrocontrollersDIY Electronics ProjectsRoboticsPrivacy PolicyTerms And Conditions