In today's rapidly evolving technological landscape, choosing the right prototyping board is crucial for engineers and hobbyists alike.

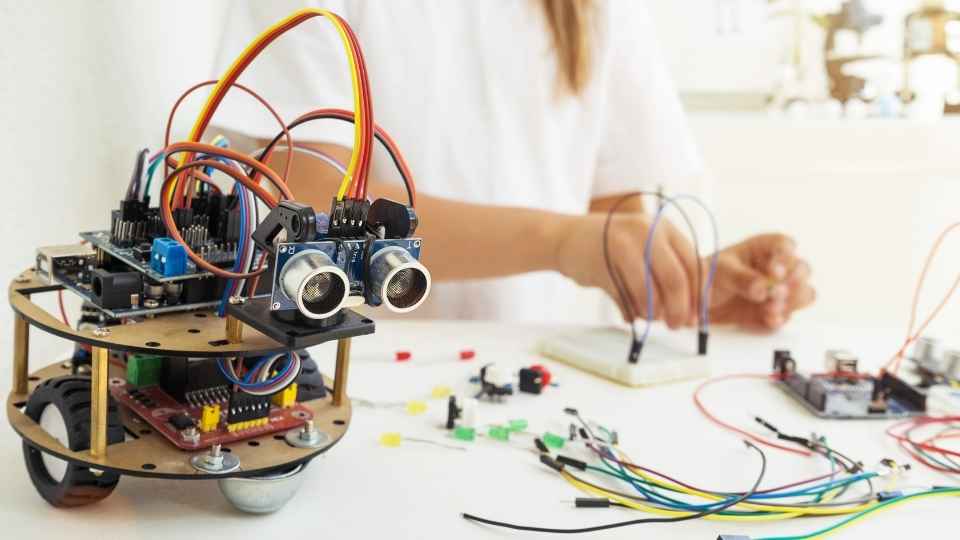

Imagine you have an innovative idea for a new electronic device, but you're unsure which prototyping board will best suit your needs.

This article aims to provide a comprehensive guide to help you make an informed decision between breadboards, perfboards, and solderable boards.

By exploring their functionality, benefits, and advantages, we will empower you to select the ideal prototyping board that aligns with your project requirements.

Key Takeaways

- The type of project, size of the project, and complexity of the circuit design are important factors to consider when choosing a prototyping board.

- Breadboards offer versatility, ease of use, reusability, and are beginner-friendly.

- Perfboards accommodate a wide range of components, offer versatility and ease of use, and allow for custom circuit layouts.

- Solderable boards provide increased reliability, improved performance, ease of assembly, and flexibility in design.

Factors to Consider When Choosing a Prototyping Board

When choosing a prototyping board, there are several factors that need to be considered. The first factor is the type of project you are working on. Breadboards are ideal for temporary or experimental projects as they allow for easy component placement and removal. Perfboards, on the other hand, offer a more permanent solution as components can be soldered onto them. Solderable boards provide even greater durability and stability but require advanced soldering skills.

Another important factor is the size of your project. Breadboards come in various sizes, allowing you to choose one that suits your needs. Perfboards and solderable boards also come in different sizes, but they may require additional cutting or modification to fit your specific requirements.

Lastly, consider the complexity of your circuit design. Breadboards are suitable for simpler designs with fewer components, while perfboards and solderable boards can accommodate more complex circuits with numerous connections.

Understanding the Functionality of Breadboards

Understanding the functionality of breadboards is essential for efficiently building and testing electronic circuits. Here are four key points to consider:

Versatility: Breadboards offer flexibility, allowing users to easily rearrange and modify their circuit designs without soldering. This makes them ideal for prototyping and experimenting with different configurations.

Ease of use: With pre-existing holes and metal strips, breadboards simplify the process of connecting components by providing a platform for quick and temporary connections.

Reusability: Components can be inserted into or removed from breadboards multiple times without causing damage. This makes breadboards a cost-effective choice for frequent circuit modifications or reiterations.

Beginner-friendly: Breadboards are often recommended for beginners due to their user-friendly nature. They provide an intuitive platform for learning about electronics without requiring advanced soldering skills.

Understanding the benefits of breadboards lays a solid foundation as we explore the advantages of perfboards in the next section.

Exploring the Benefits of Perfboards

An important aspect to consider when utilizing perfboards is their ability to accommodate a wide range of components, allowing for more complex circuit designs. Perfboards are widely used in prototyping due to their versatility and ease of use.

These boards consist of a grid of holes with copper traces running along the surface, providing connection points for electronic components. The holes on a perfboard are spaced at a standard pitch, typically 0.1 inches, which allows for easy insertion and soldering of components such as resistors, capacitors, and integrated circuits.

Additionally, perfboards offer the freedom to create custom circuit layouts by cutting or bending traces as needed. This flexibility makes them an ideal choice for creating prototypes that may require modifications during the design process.

However, if you prefer a more permanent solution or have complex designs that require smaller component sizes and higher density connections, solderable boards may be more suitable.

The Advantages of Solderable Boards

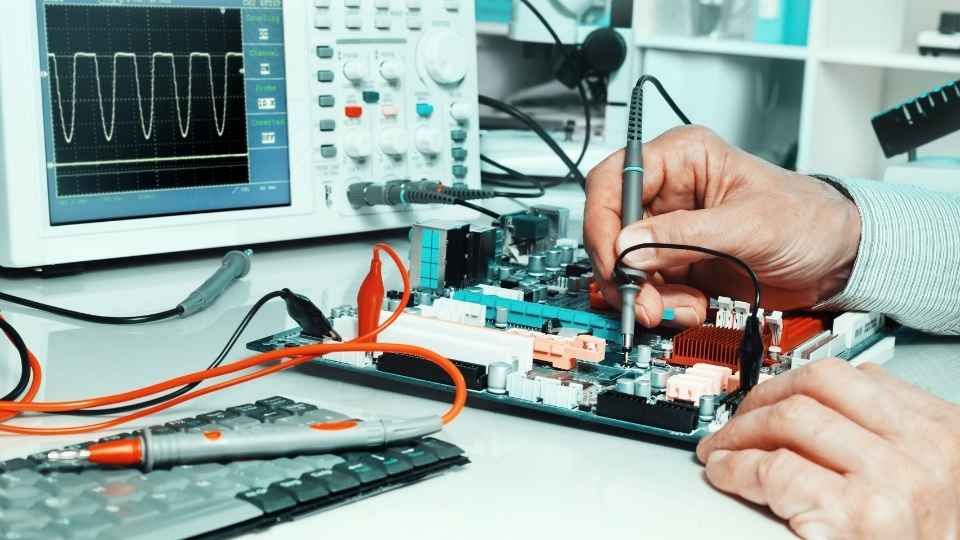

Solderable boards offer several advantages over other circuit board options. These include the ability to accommodate smaller component sizes and higher density connections for more complex designs. Here are some key benefits of using solderable boards:

Increased reliability: Soldered connections provide a secure and stable connection, reducing the risk of loose or faulty connections.

Improved performance: The use of solderable boards allows for better signal integrity and reduced signal loss, leading to improved overall performance.

Ease of assembly: With solderable boards, components can be easily mounted and secured in place, making assembly quicker and more efficient.

Flexibility in design: Solderable boards allow for greater flexibility in designing complex circuits with multiple layers and intricate routing.

Overall, solderable boards provide an excellent option for those seeking precise control over their circuit design while accommodating smaller components and enabling high-density connections.

Their reliability, performance improvement, ease of assembly, and design flexibility make them a preferred choice for many electronic projects.

Making the Right Choice for Your Project

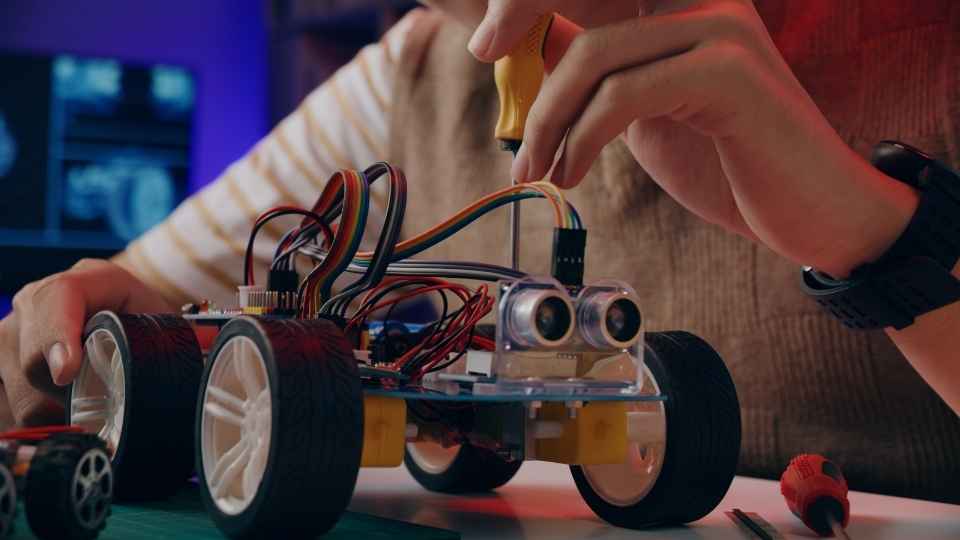

When selecting a circuit board for your project, it is important to consider factors such as compatibility with your components, required density of connections, and desired level of flexibility in design.

Each type of prototyping board - breadboards, perfboards, and solderable boards - offers its own advantages and limitations.

Breadboards are ideal for quick and temporary prototypes due to their ease of use and ability to accommodate various component sizes.

Perfboards offer more permanence and can handle higher-density designs with smaller components but require soldering skills.

Solderable boards provide the most permanent solution with a high level of flexibility in design but require advanced soldering techniques.

Ultimately, the choice depends on the specific needs of your project in terms of longevity, complexity, and personal preference for freedom in design modifications.

Frequently Asked Questions

Are There Any Specific Projects or Applications Where Breadboards Are Not Suitable?

Breadboards may not be suitable for projects or applications that require high-frequency circuits, precise signal integrity, or long-term reliability. In such cases, perfboards or solderable boards with permanent connections may be preferred.

Perfboards are designed for easy modification and reconfiguration, making them suitable for a variety of projects. Their grid-like pattern allows components to be soldered into place, providing a more permanent and stable prototyping solution compared to breadboards.

What Are the Limitations or Drawbacks of Using Solderable Boards?

Solderable boards have some limitations and drawbacks. They require soldering skills, making them less suitable for beginners. They are also less flexible than breadboards or perfboards, as components cannot be easily reconfigured or modified.

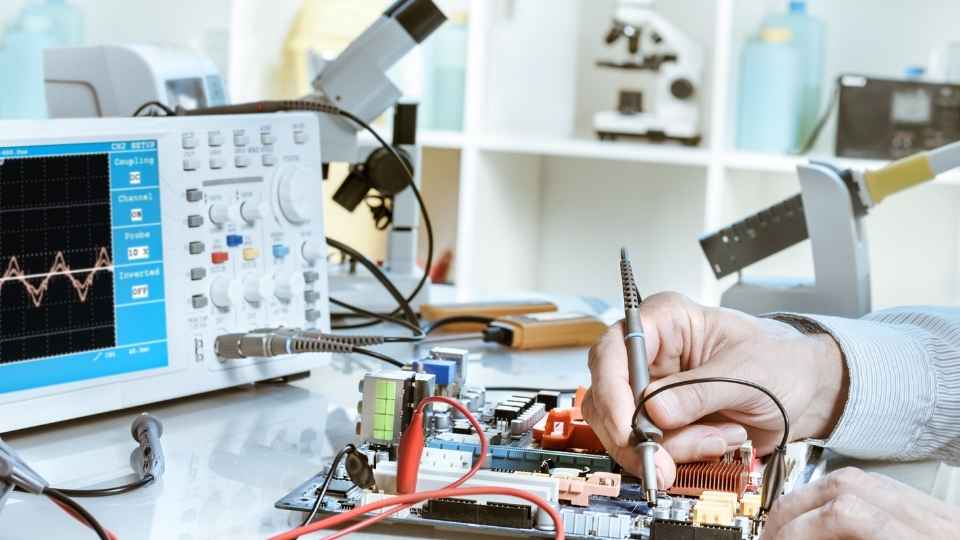

When working with perfboards, additional tools and equipment are required to ensure a successful prototyping process. These may include soldering irons, wire cutters, pliers, flux, and a multimeter for testing and troubleshooting circuits.

How Do Prototyping Boards Differ in Terms of Durability and Longevity?

Prototyping boards vary in durability and longevity based on their construction materials and design. Factors such as the type of board (breadboard, perfboard, solderable board) and the quality of components used can affect their lifespan and ability to withstand repeated use.

Basic Electronics ConceptsEssential ToolsCircuit Design BasicsMicrocontrollersDIY Electronics ProjectsRoboticsPrivacy PolicyTerms And Conditions

Basic Electronics ConceptsEssential ToolsCircuit Design BasicsMicrocontrollersDIY Electronics ProjectsRoboticsPrivacy PolicyTerms And Conditions