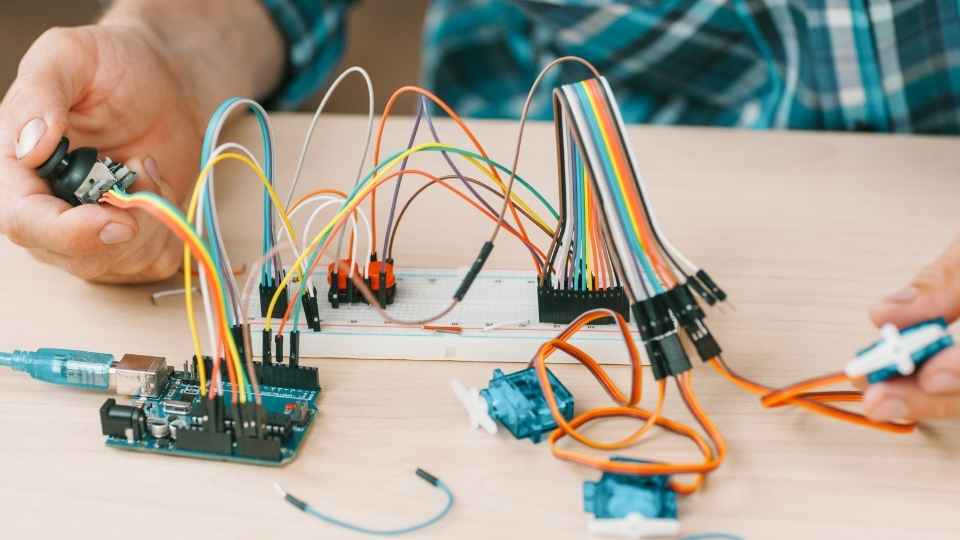

Soldering, the art of joining metal components using a heated soldering iron and a filler material, is an essential skill for newcomers in the world of electronics and DIY projects. In this comprehensive guide, we will delve into the fundamental techniques and tips that every newbie solderer should know.

From understanding the basics of soldering iron operation to exploring different joint techniques, prioritizing safety precautions, and selecting the right equipment, this article aims to equip you with the knowledge needed to confidently tackle your first soldering project.

Key Takeaways

- Familiarize yourself with the basic features of a soldering iron for safe and efficient use.

- Learn different joint techniques such as lap joint, butt joint, through-hole joint, and surface mount joint for creating strong and reliable connections.

- Follow safety precautions such as working in a well-ventilated area, wearing appropriate PPE, and keeping a fire extinguisher nearby.

- Select the right equipment for soldering, including soldering irons with adjustable temperature settings, flux core solder wire, and suitable solder wire diameter. Consider budget-friendly options that offer good heat transfer and stability.

Understanding Soldering Iron Basics

Understanding the basics of a soldering iron is crucial for newcomers to effectively master the art of soldering.

A soldering iron is a handheld tool used to melt and join metal components together using solder.

It consists of a heated metal tip, an insulated handle, and a power cord connected to an electrical source.

The temperature of the soldering iron can be adjusted depending on the type of material being worked on. This allows for precise control over the melting point and flow rate of the solder.

Additionally, different types and sizes of tips can be attached to the iron to accommodate various soldering tasks.

It is essential for beginners to familiarize themselves with these basic features in order to ensure safe and efficient use of the tool.

Exploring Different Joint Techniques

To gain expertise in the art of soldering, it is crucial to familiarize oneself with various joint techniques employed by professionals. These techniques are essential for creating strong and reliable connections between electronic components.

Here are two sub-lists that will help you understand and master different joint techniques:

1. Mechanical Joints:

- Lap Joint: Overlapping two surfaces and soldering them together.

- Butt Joint: Joining two surfaces end-to-end.

2. Thermal Joints:

- Through-Hole Joint: Inserting components through holes on a PCB and soldering them from the other side.

- Surface Mount Joint: Attaching components directly onto the surface of a PCB using small pads.

Prioritizing Safety Precautions

Safety precautions should always be prioritized when working with electronic components to minimize the risk of injury or damage. Soldering involves the use of high temperatures and potentially hazardous materials, making it important to take necessary precautions.

To begin, ensure that you are working in a well-ventilated area to prevent inhalation of harmful fumes. It is crucial to wear appropriate personal protective equipment (PPE), such as safety goggles and heat-resistant gloves, to protect yourself from burns and other injuries. Additionally, keep a fire extinguisher nearby in case of emergencies.

By following these safety measures, you can create a secure environment for soldering operations while safeguarding your well-being and that of others around you.

Transition: Now that we understand the importance of safety precautions, let's move on to selecting the right equipment for soldering.

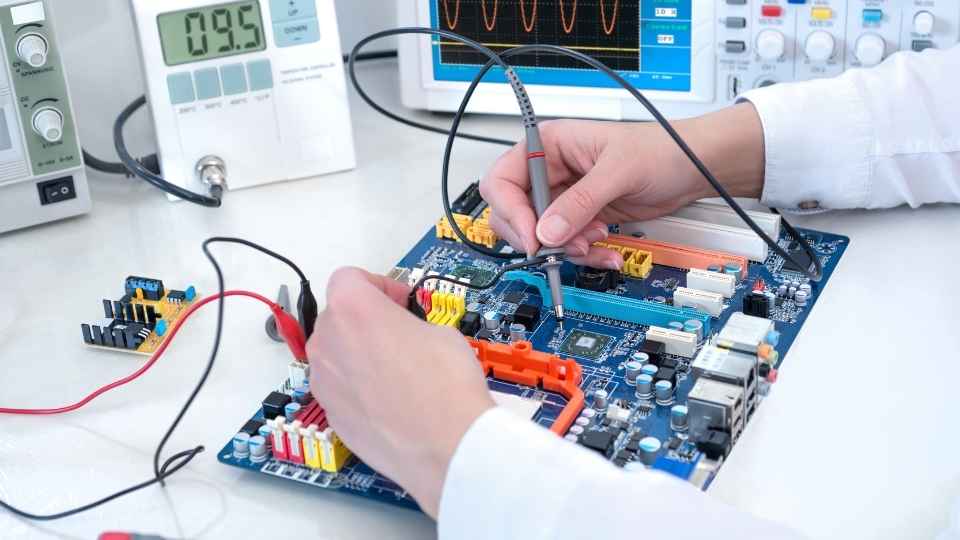

Selecting the Right Equipment for Soldering

When it comes to selecting the right equipment for soldering, there are several essential considerations to keep in mind.

It is important to choose equipment that is suitable for your specific soldering needs and requirements.

Additionally, budget-friendly options are available that can still provide reliable performance and quality results.

Equipment: Essential Considerations

Proper equipment selection is crucial for ensuring optimal results in the soldering process. When it comes to choosing the right equipment, there are several essential considerations that need to be taken into account:

Quality of Soldering Irons:

Look for irons with adjustable temperature settings and a variety of interchangeable tips.

Consider investing in high-quality soldering irons that offer good heat transfer and stability.

Solder Wire Selection:

Opt for flux core solder wire as it helps facilitate the flow of solder and improves adhesion.

Choose a diameter suitable for your project, typically ranging from 0.6mm to 1.2mm.

Budget-Friendly Soldering Options

Affordability is a key consideration when exploring options for soldering equipment that fit within a limited budget. Fortunately, there are budget-friendly soldering options available that do not compromise on quality or performance.

When it comes to choosing soldering irons, look for models with adjustable temperature control and interchangeable tips, as these features provide versatility and precision. Additionally, investing in a soldering station can offer better temperature stability and safety features compared to standalone irons.

For those on an even tighter budget, consider purchasing entry-level soldering kits that include all the necessary tools and accessories. These affordable options allow beginners to get started without breaking the bank.

Mastering essential soldering tips will further enhance your skills and ensure successful results in your projects.

Transition: Now that we have explored some budget-friendly soldering options, let's move on to mastering essential soldering tips for beginners.

Mastering Essential Soldering Tips

To become proficient in soldering, it is crucial to master essential tips that will enhance your technique and ensure successful connections. Here are some key tips to help you improve your soldering skills:

Choose the right soldering iron: Use a soldering iron with adjustable temperature control to avoid overheating or underheating the components.

Prepare the workspace: Clean and organize your work area to minimize distractions and potential hazards.

Use a heat-resistant mat or surface: Protect your workspace from accidental burns or damage caused by hot soldering irons.

Ensure good ventilation: Work in a well-ventilated area or use fume extraction equipment to avoid inhaling harmful fumes.

By following these tips, you can achieve precise and reliable solder connections, enabling you to pursue various projects with freedom and confidence.

Best Practices in Soldering for Newbies

For beginners in the field, it is crucial to establish a solid foundation by adhering to industry-approved methods and safety protocols when engaging in soldering projects. Soldering, the process of joining two metal components using a filler material called solder, requires precision and attention to detail. To ensure optimal results and minimize potential hazards, newbies must follow best practices in soldering.

Firstly, it is essential to select the appropriate tools and equipment for the job. This includes a soldering iron with adjustable temperature settings, high-quality solder wire, flux, and safety gear such as heat-resistant gloves and goggles. Additionally, beginners should familiarize themselves with the different types of solders available for various applications.

Furthermore, proper preparation of both the work surface and the components to be soldered is crucial. This involves cleaning them thoroughly to remove any dirt or contaminants that could interfere with the bonding process.

Lastly, practicing good technique is vital for successful solder joints. This includes heating both the component and the solder evenly while avoiding excessive heat that could damage sensitive parts.

Frequently Asked Questions

Can Soldering Iron Tips Be Replaced or Do I Need to Buy a New Soldering Iron?

Soldering iron tips can be replaced without needing to purchase a new soldering iron. By replacing the tip, you can maintain optimal performance and extend the lifespan of your soldering iron, saving you time and money in the long run.

How Do I Clean My Soldering Iron Tip and Ensure It Stays in Good Condition?

To maintain a soldering iron tip and ensure its longevity, regular cleaning is essential. Use a damp sponge or brass wire brush to remove excess solder and oxidation. Proper maintenance increases the lifespan of the tip, saving money on replacements.

What Is the Difference Between Lead-Based Solder and Lead-Free Solder?

Lead-based solder contains lead as a primary component, providing excellent conductivity and ease of use. Lead-free solder, on the other hand, is formulated without lead due to environmental concerns, requiring higher temperatures for melting and potentially leading to weaker joints.

Is It Necessary to Use Flux When Soldering, and if So, How Do I Apply It Correctly?

Yes, using flux is necessary when soldering as it helps to remove oxidation and improve the flow of molten solder. To apply it correctly, simply add a small amount to the joint before heating with the soldering iron.

How Do I Prevent Solder Joints From Cracking or Breaking Over Time?

To prevent solder joints from cracking or breaking over time, it is important to ensure a clean and secure connection. This can be achieved by using the appropriate soldering techniques, such as applying the correct amount of heat and using suitable soldering materials.

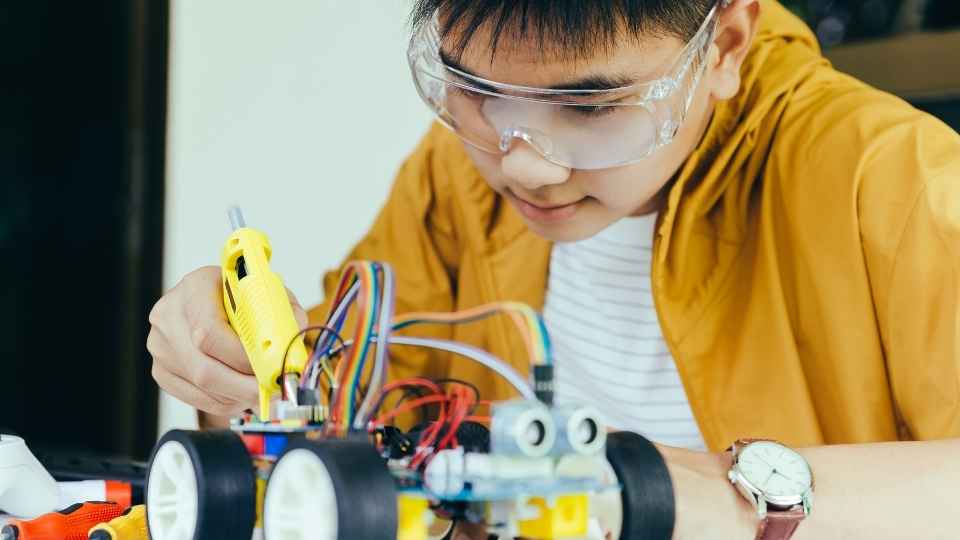

Basic Electronics ConceptsEssential ToolsCircuit Design BasicsMicrocontrollersDIY Electronics ProjectsRoboticsPrivacy PolicyTerms And Conditions

Basic Electronics ConceptsEssential ToolsCircuit Design BasicsMicrocontrollersDIY Electronics ProjectsRoboticsPrivacy PolicyTerms And Conditions